Material Processing

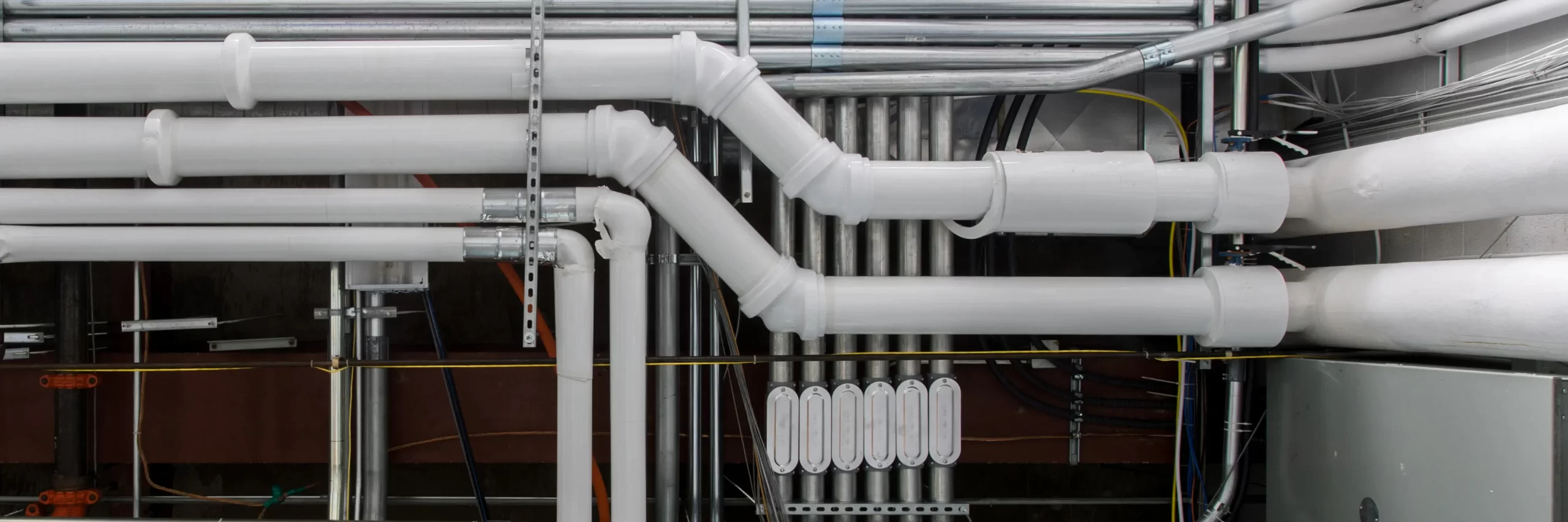

PVC Polyvinyl Chloride

PVC is a synthetic resin made from the polymerization of vinyl chloride that is widely used as a commodity thermoplastic. It is the third most-widely produced thermoplastic as it boasts high chemical resistance, durability, and mechanical properties.

The solution

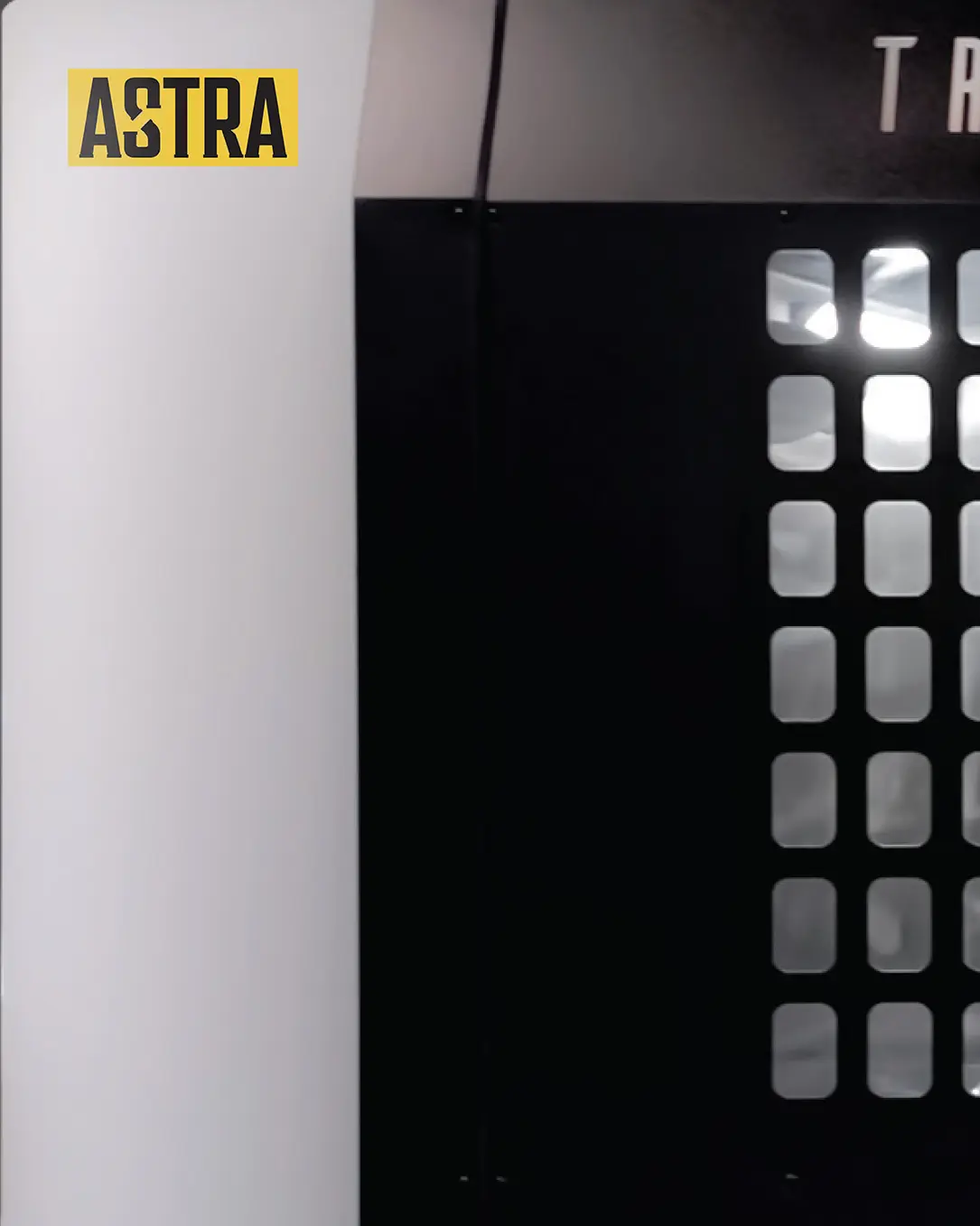

Tradesman Series™ P3-44 ASTRA

Confidently process PVC materials with the P3-44, a custom-designed large format pellet 3D printer from our Base Tradesman Series™ P3-44. This model offers advanced process controls to ensure PVC printing, utilizing specialized systems for fume prevention, containment, extraction, and environmental protection.

ASTRA is engineered to handle the unique challenges of PVC with galvanic corrosion-resistant components and targeted fume extraction at the point of print deposition. Designed with operators in mind, this printer is production-ready for high-demand environments, offering superior chemical resistance, flame resistance, and long-term durability in printed parts. Deliver consistent results while prioritizing safety and efficiency where robust, reliable PVC printing capabilities are required.