Ready to find out more?

Drop us a line today for a free quote!

What is ABS?

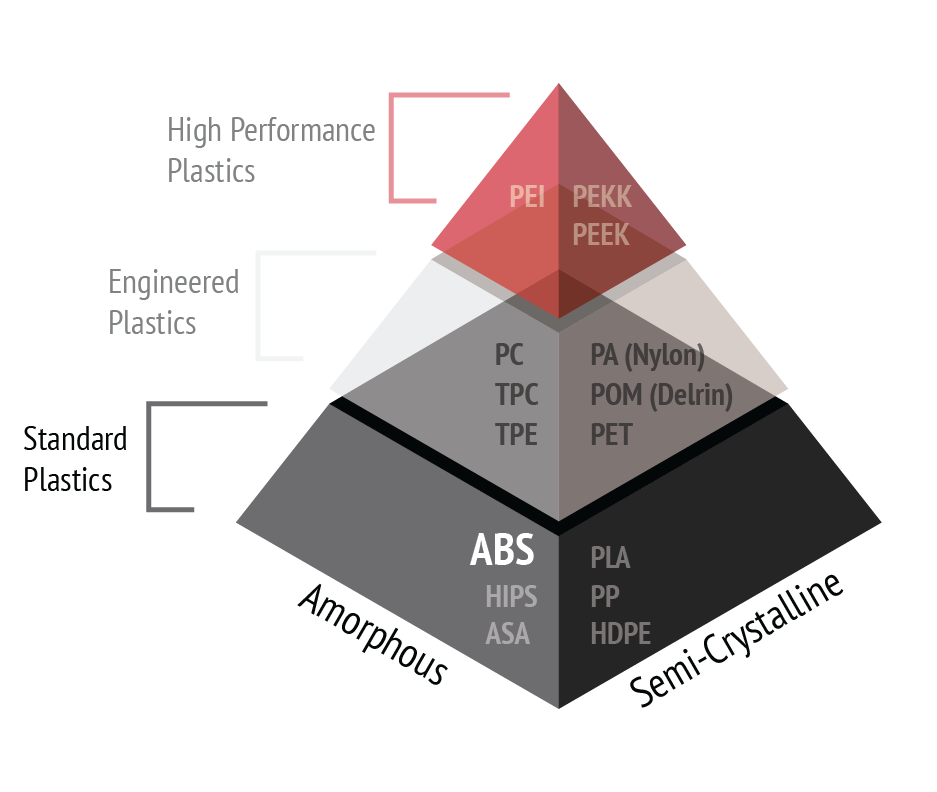

Acrylonitrile butadiene styrene (ABS) is an amorphous thermoplastic. Like many 3D printing filaments, ABS possesses the unique ability to melt when heated at specific temperatures, cool, and be heated again without considerable degradation. As an amorphous polymer, ABS does not have a true melting point, but rather liquifies over a broader range of temperature. ABS is known for its impact resistance and toughness, and can be found in a number of commercial and industrial applications. It has emerged as a popular filament for 3D printing due to its wide availability and relative ease of printing.

What can you use ABS for?

ABS can be used for general purpose 3D printing, including prototypes and fixtures, but can also serve in more demanding applications like maritime tooling and industral production parts. ABS is generally considered a commodity or lower-grade engineering thermoplastic, and its use may be limited where higher strength or temperature resistance is required.

ABS FOR 3D PRINTED TOOLING

As a 3D printing material available for a reasonable price that demonstrates good mechanical performance and can be easily post-processed, ABS is a material that can be used to produce:

- Patterns for sand casting

- Molds for thermoforming

- Check gauges

- Assembly aides and fixtures

ABS FOR 3D PRINTED PROTOTYPES

ABS can be used to create functional prototypes that exhibit similar traits compared to plastic parts made with similar materials in the following processes:

- Injection Molding

- Thermoforming

- Extrusion

- Rotational Molding

Consult your engineering team to understand the limitations for 3D printed parts compared to those made traditionally.

ABS FOR PRODUCTION 3D PRINTING

ABS filament is a 3D printing material suitable for some production programs, for example:

- Automotive instrument panels

- Food processing components

- Vehicle bumpers

- Plumbing components

- Electrical housings and covers

- Machine or tooling guards and housings

ABS Performance Features

- Resistance to corrosive chemicals and/or physical impacts.

- Easily mended by sanding, drilling, or machining.

- Ability to be painted, joined (through adhesives or welding techniques), and plated.

- Good electrical insulation properties

- Resistance to low temperatures

ABS Material Properties

Typical properties for molded ABS test specimen include:

- Tensile Strength: 29.6 - 48.0 MPa

- Tensile Modulus: 1,790 - 3,200 MPa

- Elongation at Break ≅ 53%

- Elongation at Yield ≅ 5.5%

- Flexural Strength: 60.6 - 73.1 MPa

- Flexural Modulus: 1,600 - 2,400 MPa

- Glass Transition Temperature ≅ 108°C

- Heat Deflection Temperature (1.8 MPa): 70°C - 89°C

- Hardness ≅ Shore D 100

- Density: 1.01 - 1.20 g/cc

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

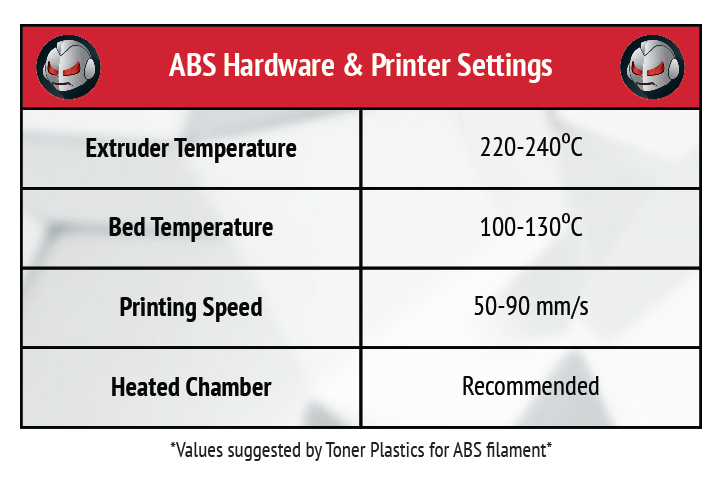

PRINTER Requirements AND SETTINGS

Due to its high glass transition temperature, a heated bed is required to successfully print with ABS. For the best results when printing with ABS, a fully enclosed print bed is recommended.

While the ranges may not vary greatly from brand of material to another, operators should always check for the suggested printing parameters, provided by the material manufacturer. Your machine manufacturer can also be a great resource for processing knowledge.

Toner Plastics suggests the extruder temperature be set between 220℃ and 240℃, the bed temperature to be set between 100℃ and 130℃, and for the printing speed to be 50-90 millimeters per second. You can find out more from their distributor, Curbell Plastics.

3D Printing with ABS - the procedure

ABS requires a specific printing environment to avoid causing the print to have too much internal stress, which will warp the print significantly. While an enclosure is not required to print small parts in ABS, it is important when printing medium to large sized parts. When printing ABS on these printers, we recommend closing the lid to maintain a higher internal temperature. When drying, the most efficient way to do so is to put it in the oven at about 80°C for four to six hours.