Ready to find out more?

Drop us a line today for a free quote!

3D PRinted PETG APPLICATIONS

PETG is commonly used in vacuum and pressure forming applications due to its low forming temperatures. PETG is also well suited for routing, bending, and die cutting. The material can be found in a variety of consumer and commercial applications, including;

- Retail and medical packaging

- Advertising displays

- Electronic insulators

- Food containers and bottles

- Protective equipment and parts

In 3D printing, PETG is almost as easy to print as PLA, with an additional heat resistance and more durability. It comes in a wide variety of colors which makes it ideal for more functional or demanding applications where PLA would lack performance. Because of this, it can be a popular material amongst product design teams for prototyping purposes.

PETG PERFORMANCE FEATURES

- Ease of printing

- Good layer adhesion

- Good light diffusion

- Significant chemical resistance

PETG Material Properties

Typical properties for 3D printed PETG test specimen, according to Polymaker, include:

- Tensile Strength (XY Direction): 31.9 ± 1.1 MPa

- Tensile Strength (Z Direction): 13.4 ± 2.0 MPa

- Tensile Modulus (XY Direction): 1,472 ± 270 MPa

- Tensile Modulus (Z Direction): 1,087 ± 79 MPa

- Tensile Elongation at Break (XY Direction): 6.8 ± 0.9%

- Tensile Elongation at Break (Z Direction): 1.3 ± 0.2%

- Flexural Strength (XY Direction): 53.7 ±2.4 MPa

- Flexural Modulus (XY Direction): 1,174 ± 64 MPa

- Glass Transition Temp: 81℃

- Density: 1.25 g/cm3 at 21° C

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

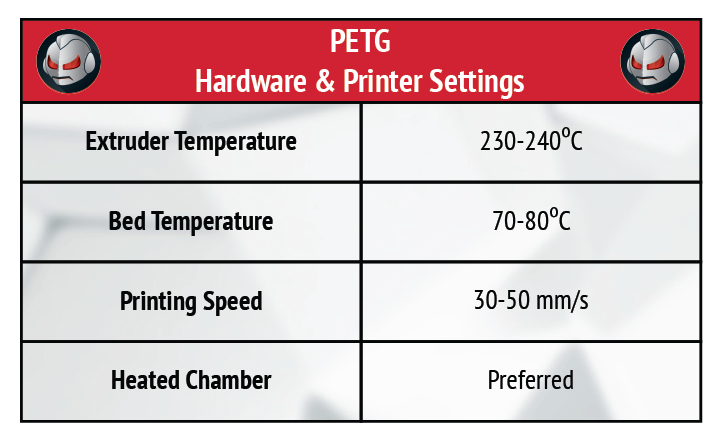

Printer Requirements and Settings for PETG

Different brands and strands may require different processing parameters or configurations of the 3D printer. Operators should always check for the suggested printing parameters provided by the material manufacturer; they will be the greatest resource for processing knowledge.

3D printing material producer Polymaker currently offers PolyLite™ PETG, for which they suggest a print speed of 30-55mm/s, and states that preferred extruder temperature is in the range of 230-240℃. They recommend setting the bed temperature between 70-80℃. Drying should occur at 65℃ for 6 hours for optimal printing quality.