JuggerBot 3D, Airtech Extend Material Card Suite to High-Temperature Tooling Resins

The collaboration focuses on developing parameters for repeatable & reliable printing of Dahltram® I-350CF.

July 5, 2024

Youngstown, Ohio & Springfield, Tennessee (June 27, 2024) — Industrial 3D Printer OEM JuggerBot 3D announces the significant addition of Airtech Advanced Materials Group’s Dahltram® I-350CF, a 20% Carbon-Fiber reinforced Polyetherimide (PEI), to their Material Card suite.

Airtech Advanced Materials Group, a leader in specialty additive manufacturing materials, offers an expansive portfolio of thermoplastics that consistently serves leaders in the aerospace, high-performance automotive, marine, and motorsport sectors. 3D printed tools and end-use parts contribute to increased efficiency, flexibility, and aerodynamics during use.

“The qualification of Dahltram® I-350CF through JuggerBot 3D’s Material Card platform further signifies our commitment to progress in additive manufacturing by collaborating with an industry-leading OEM geared to fuel innovation in the markets we serve.” stated Gregory Haye, Director of Additive Manufacturing at Airtech Advanced Materials Group.

The Material Card is moving to the apex of high-performance thermoplastics with Dahltram I-350CF being the newest addition for JuggerBot 3D users. First unveiled at RAPID+TCT 2023, this digital suite addresses skills gaps and streamlines operation, leveraging findings from material testing to fuel data-driven process control. Material Cards also provide critical safety and material properties for 3D printed parts, helping engineers and designers better predict performance of printed items.

Airtech is a global leader in 3D printing, offering great materials for production molds, dies, forms and fixtures. They add deep expertise in design and preparation of 3D printed tools, as well.” Fernback continued “The I-350CF Material Card and collaboration with Airtech enhances our user’s ability to deliver high quality tooling and parts that are critical to their customers.

Daniel Fernback

Vice President, JuggerBot 3D

Forming Integrity between Large Format Printing and High-Temperature Composites

As soon as we started running PEI, it became very clear why the Material

Derek King

Card exists. It’s the best way to build.

Research Technical Lead, Weber State University MARS Center

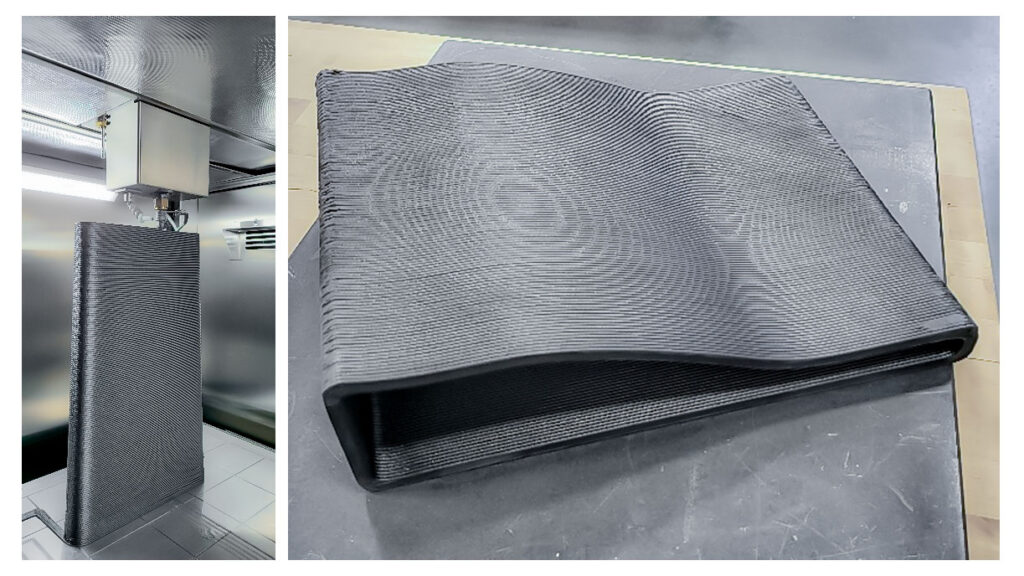

The Tradesman Series™ P3-44, known for its robust construction and capability, is designed to handle large-format printing of a wide range of performance thermoplastics. Its advanced features, including its heated build chamber, precision control systems, and sophisticated calibration processes make it an ideal platform for leveraging the unique properties of Dahltram® I-350CF.

Airtech’s screening process for the qualification of Dahltram® parameters on the Large Format Pellet System establishes baseline mechanical, and physical properties such as Tensile Strength/Modulus, Elongation at break, Flexural Strength/Modulus, Coefficient of Thermal Expansion (CTE), Glass Transition Temperature (Tg), and more. Coupling this rigorous testing process with JuggerBot 3D’s Material Testing & Assessment procedure, large areas of process parameters are defined for the successful repeatability & reliability of each print.

Weber State University’s Miller Advanced Research and Solutions (MARS) Center, a Utah based

composites center with the goal to address industry deficiencies in high-temperature composites supporting hypersonic vehicles, rocket motors, and other energy and space applications, were the first users of the Dahltram® I-350CF Material Card. “As soon as we started running PEI, it became very clear why the Material Card exists,” commented MARS Center Research Technical Lead Derek King. “It’s the best way to build”.

The collaboration between JuggerBot 3D and Airtech Advanced Materials Group provides promise for new advancements in the development of tooling & end use part production to meet necessary industry needs. For more information on the Dahltram® tooling resin portfolio and Airtech Advanced Material Group, visit www.airtech.com

About JuggerBot 3D

JuggerBot 3D is an additive manufacturing OEM specializing in large format systems capable of processing performance materials. Moreover, We strive to design and build the finest 3D printing solutions in the world while delivering technology that meets our customers’ criteria for performance, reliability, and value. JuggerBot 3D proudly manufactures their systems in Youngstown, Ohio. To learn more about JuggerBot 3D and for project updates, visit www.juggerbot3d.com.

About Airtech Advanced Materials Group

Airtech Advanced Materials Group is a leading innovator in the development and manufacture of advanced composite materials. With a focus on high-performance applications, Airtech provides a wide range of products and services designed to meet the demanding requirements of industries such as aerospace, automotive, marine, and wind energy. For more information, visit www.airtech.com.

Contact

Benjamin Toomey

Marketing Manager, JuggerBot 3D

[email protected]

(330)-331-2190

juggerbot3d.com

Lindsay Dahlgren

Email: [email protected]

airtech.com