JuggerBot 3D

Blog

Is PVC a Viable 3D Printing Material?

Understand whether PVC is a suitable and cost-effective material for 3D printing—and how JuggerBot 3D enables it in industrial applications.

By Ben Toomey

June 3, 2025

The PVC question has plagued the additive manufacturing (AM) industry for the better part of a decade. Why has the third largest produced polymer with desirable material benefits at a fraction of the cost of other commodity-grade thermoplastics not been encouraged by material providers and OEMs alike? As we at JuggerBot 3D have stepped into the arena by developing a system to handle the challenges presented by PVC (Polyvinyl Chloride) an even larger natural question arises: Is PVC a viable 3D Printing Material?

Being so widely produced and versatile, PVC is found everywhere: from the vinyl records lining the walls of my apartment to housings in the MRI machines at our local hospital. Two years ago, I was helping a friend replace the trap under her sink with a flexible PVC component. My father told me that the choice of PVC would last longer than the cast metal part that corroded out over its years of service at a fraction of the price. Due to its promising properties and tailorable performance the material has a unique value proposition in terms of utility. These advantages do not arrive without a level of scrutiny tied to claims of its environmental impact and lack of sustainability. In AM, concerns of PVC are found in the processing and production of parts using this material due to the potential for degradation and harm to operators.

Eleven days after installing the new trap and some twenty-one miles away from the JuggerBot 3D home office, a train derailed in East Palestine, Ohio. The freight on board included 129,000 gallons of Vinyl Chloride, the primary monomer in PVC. Concerns of liver failure and the carcinogenic fallout still affect the surrounding communities. I will spare you the details and imagery from the event, but many in the Northeast Ohio area still recovering from the disaster even a few years later.

Safely Breaking Down PVC

As a background, vinyl chloride monomers (VCMs) are regulated under the Toxic Substances Control Act and designated by the EPA as a high-priority chemical due to their potential for causing health and environmental harm at varying levels of exposure. High degrees of standardization are at play when it comes to material handling. As VCMs go through polymerization, they are bound into the polymer structure and are understood as stable. The monomer is now seen as non-reactive under normal use conditions and results in a durable, chemically resistant form. There is a repository of reports supporting this claim, especially for studies addressing concerns about VCM leaching into drinking water.

It must be addressed that PVC can become volatile again if not processed correctly, chiefly if it reaches critical Degradation Temperature (Td). Instead of returning back to VCM, offgassing of Hydrochloric Acid (HCL) and Dioxins occurs. In outfitting a system capable of printing PVC, process controls to address this potential hazard are paramount.

PVC Material Properties

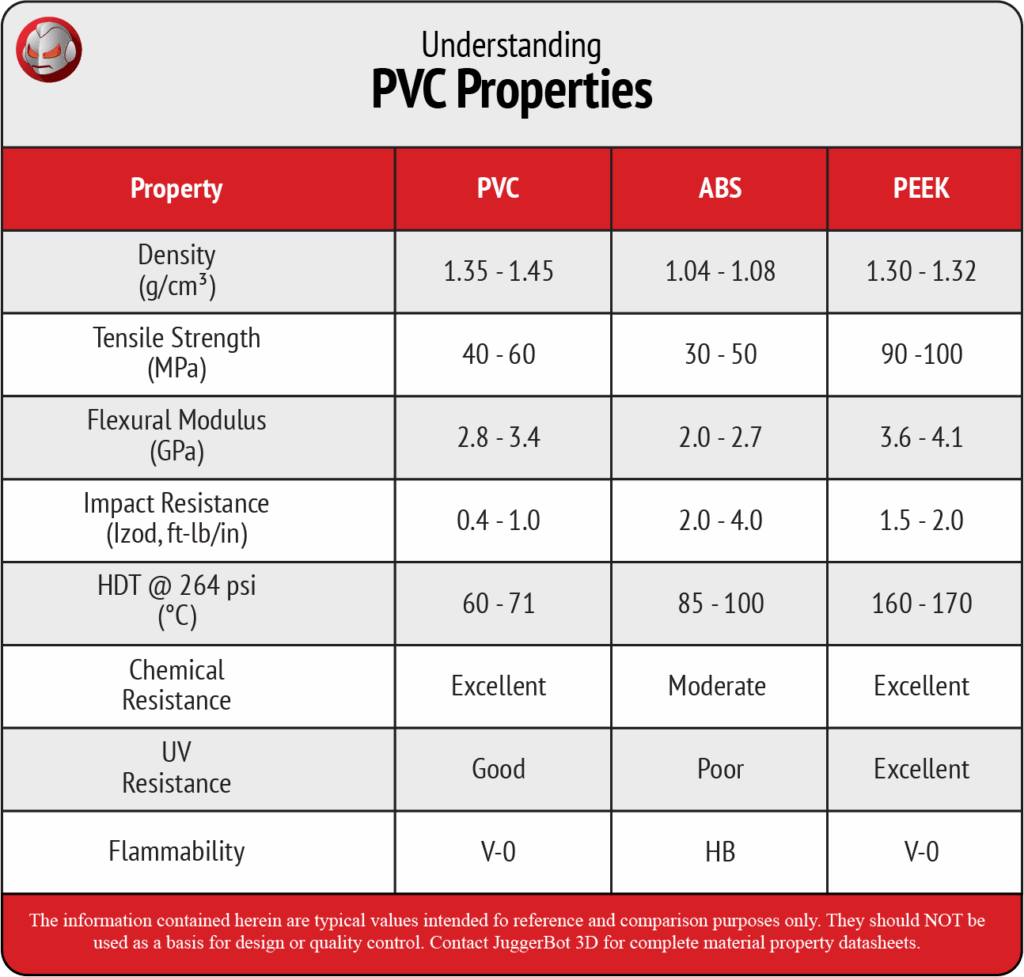

Though tailorable for functionality, Polyvinyl Chloride features prominent and utility-focused properties. First, PVC is well known for its strong chemical resistance — especially to salts, acids, and bases. PVC is also highly corrosion-resistant, even when exposed to alcohols, fats, and oils, often used as a replacement for various metals. The chart provided shares relative chemical resistance for PVC in comparison to other common 3D printing materials.

Durability is another area where PVC shines, demonstrating resistance to wear and tear, enabling parts manufactured with this material to withstand harsh environmental conditions. Due to the composition of PVC, the material is also inherently flame retardant. It is a self-extinguishing material based on UL’s flammability tests. The chart below provides a general comparison of PVC mechanical properties against other common 3D printing materials based on conventional test specimens.

Interested in how PVC could fit into your 3D printing strategy?

We’ve helped manufacturers understand new applications with AMPVC—backed by rigorous process control and real-world validation. Let’s talk applications →

PVC Printing in an Industrial Environment: Use & Application

Pipes and fittings for water supply, drainage, and sewage systems

- Leverages chemical and corrosion resistance (especially to chlorinated water, making it great for municipal water systems, pools and wastewater systems).

- Reduces installation pricing.

- Long service life.

- Helps reduce energy costs in pressurized systems (this may not apply to 3D printed parts since we don’t offer smooth surfaces without post-processing).

- Non-conductive and insulating, reducing risks of stray electrical currents.

- Meets many building codes, especially where UL 94 V-0 is required.

Medical equipment and healthcare, including trays, hygienic surfaces, partitions, and enclosures

- Easily sterilized using a variety of methods, which is essential for hygiene and infection control.

- Resists many body fluids, medications, disinfectants, and gases used in medical settings.

- Has a long history of FDA and EU compliance in healthcare, simplifying the product approval process.

Industrial and chemical tanks, ducting, and ventilation systems

- Great resistance to chemicals, especially acids, bases, salts and common industrial chemicals.

- Unlike metals, will not rust, corrode, or degrade when exposed to moisture or harsh substances.

- Can be welded, machined, formed, or molded into various shapes, making it easy to fabricate desired shapes and assemblies.

- Good mechanical strength and dimensional stability.

- Low maintenance – generally doesn’t enable buildup and is easy to clean without coatings or paint.

- Can be great for outdoor applications, especially for PVC grades that include UV stabilizers.

- Lightweight

- Easily compatible with a wide variety of fittings and accessories.

Electrical enclosures

- Helps prevent short circuits and safely houses electrical components due to PVC being a natural insulator.

- Rigid PVC is self-extinguishing, reducing risk of fire spread within panels or junction boxes.

- Corrosion and moisture resistant.

- Will not interfere with sensitive electronic or communication signals.

- Easy to integrate, as many gaskets, seals, fittings, and hardware are widely available for PVC enclosures.

Dashboards, panels, and trims for various methods of transportation

- Compatible with many methods to finish, including textures, paints, and coatings.

- Many grades of PVC are formulated to resist fading, warping, and degradation under sun exposure and high cabin temperatures.

- Enhances vehicle fire safety, complying with UL or FMVSS standards.

Packaging, signage, and displays – especially for sturdy, outdoor installations

- Great barrier properties, offering strong resistance to moisture, gases and chemicals, protecting and preserving contents.

- Rigid PVC is tough and puncture-resistant, helping prevent damage in transit or handling.

- Weather and UV resistant

- Compatible with a wide range of finishes.

- Easily customized through machining, bending, cutting, molding, gluing, etc.

3D Printing Applications for PVC

In 2023, our team was approached by IPEX Technologies, a global leader in thermoplastic piping solutions, to test the feasibility of 3D printing one of their product lines, a Vortex Flow Inset (VFI). VFIs, simply put, are not what most would define as a “sexy” application. The VFI is a variable-size component placed in vertical sewer drop systems to suppress noxious fumes in wastewater and ultimately reduce corrosion and odorous gases. Just writing that I can hear the audible cringe from those looking forward to hearing about PVC used in electrical enclosures for the F-35 Lightning II. The Vortex was conventionally manufactured with several sections, often resulting in major costs revolving around labor.

IPEX worked with our team in designing for additive manufacturing with success to speak to the primary north stars of 3D printing: part consolidation, time for iteration and production, and cost. Initially, the VFIs were produced with ABS as it still features corrosion resistance, but the larger idea of PVC lingered. The challenge was presented, contracts were signed, and the Tradesman Series™ P3-44 ASTRA (variation on the base LFAM unit) was created.

Building a PVC 3D Printer

To meet the challenges presented by PVC’s nature, the approach our engineering team took was not incidental—but purposeful and research driven. Through this, major areas were derived for the confident processing of the material:

- Prevention: Construction materials and components were carefully selected to extend the 3D printer’s lifespan while ensuring critical PVC processing conditions. ASTRA has been outfitted with corrosion-resistant hardware, tailored programming, and key control components to prevent mishandling.

- Containment: Processing PVC may release fumes that could be harmful over time, making proper containment essential for workplace safety. Additional sealing areas across the already enclosed base P3-44 ensure fumes generated during printing stay within controlled zones.

- Dedicated Fume Extraction: Equipped with a dual-stage fume extraction system, ASTRA captures fumes emitted throughout the printing process.

- Operator Protection: Improper processing of these materials can produce issues in the production environment. Access to the chamber is prohibited to prevent premature access, ensuring the environment is clear of fumes before the system is opened.

Through these actions, we aimed to limit operator exposure and the risk of degrading the polymer to a point where it becomes dangerous to both the user and environment.

Challenges in 3D Printing PVC

Processing AMPVC is not without its unique set of hurdles. Some of the primary challenges we noted in processing PVC include:

- Corrosion: PVC can produce galvanic corrosion to internal system components, which is highly destructive to machine integrity.

- Temperature Control: PVC’s potential for degradation with a narrow window for residence time creates the need for control over printhead, bed, and ambient temperatures.

- Acceptance with Traditional Methods: AMPVC aims to work alongside traditional manufacturing rather than as a replacement. Injection molding has been the standard, but requires tooling, time, and volume. Additive allows for rapid iteration and lower part necessities without tooling delays.

- Challenging Other AM Polymers: PVC competes with established AM materials like ABS, ASA, and PETG. While these are conventionally more available, they don’t offer the same chemical resistance or cost-effectiveness in certain industrial requirements.

Challenges such as these can prove to be potentially destructive, a primary driver in the hesitance to make this material accessible to the industrial market. Working with a vertically integrated manufacturer of materials and pipes in IPEX Technologies has led to the formation of AMPVC with stabilizers and plasticizers suited for the LFAM market, with the opportunity for more tailored solutions for demanding markets.

So, is PVC a Viable 3D Printing Material?

Yes, but under the right operating conditions. Using AMPVC is not about loading the material into a system and pressing print; rather, it is about having a detailed understanding of the potential issues concerning the breakdown of the material and having components within an additive manufacturing process that can protect both the operator and the system. When done correctly, a new opportunity for cost-effective, property-rich parts that rival commodity-grade and high-performance materials is presented.

At JuggerBot 3D, we’re proud to be a leading voice and supplier in creating a pathway for making PVC a trusted and confident material for part production in additive manufacturing. If you’d like to be at the forefront of 3D printing with PVC, reach out and we can see where this material fits in your production process.

ABOUT BEN TOOMEY Ben Toomey, Marketing Manager, joined JuggerBot 3D in 2022. He leads content strategy and development for all JuggerBot 3D marketing efforts, exploring where large format additive manufacturing and relative industry verticals meet. ABOUT JUGGERBOT 3D JuggerBot 3D is an additive manufacturing OEM specializing in large-format systems capable of processing performance materials. We design and build advanced 3D printing solutions that meet our customers’ criteria for performance, reliability, and value. JuggerBot 3D proudly manufactures its systems in Youngstown, Ohio.