CNC Machining vs 3D Printing

CNC Machining vs. 3D Printing

In the process of developing a product, there are several different options one could decide to use to create a prototype. CNC Machining and 3D printing are two of the most commonly used rapid prototyping processes. The major similarity between the two is that they can both produce small quantities at a low cost. They also both use CAD design to create their models.

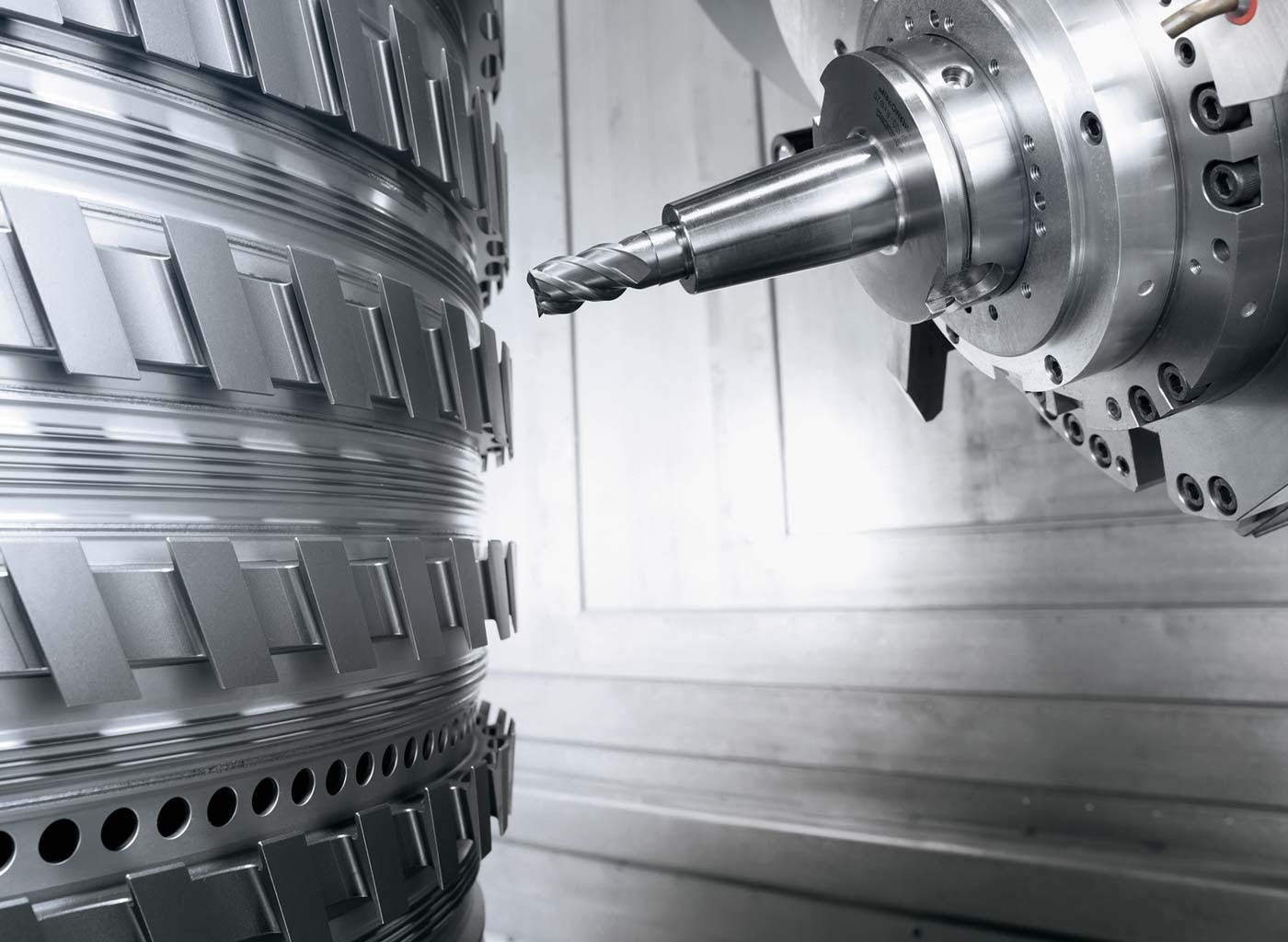

CNC Machining

This is the process of drilling or cutting from a big block of material. There are a wide variety of materials that CNC Machining can utilize, but metal is the most commonly used.

-Classifies as a subtractive manufacturing technology. The process begins with a solid block of material and removes material to create the final shape.

-3D printers can usually only process one type of material depending upon what type of printer it is (ex: FDM printers can only process thermoplastics), CNC machines can usually process multiple different types

-Does not require removal of support materials

-Better at producing robust and heat-resistant objects

-Best fitted in medium to high quantities

3D Printing

3D printing is the process of extruding material layer by layer to create a three-dimensional object.

-Classifies as additive manufacturing, which builds material up layer-by layer to create the final shape.

-Free design complexity is one of the huge benefits to using 3D printing opposed to CNC Machining.

-Tends to be lower in cost, with a faster turn-around

-3D printing has a wider range of applications (ex. casting, biopolymers, aerospace)

It is important to keep the benefits and limitations to both in mind so the parts are manufactured to best suit the needs of the project. Complexity and the number of parts needed are key in selecting the appropriate manufacturing process.