Research & Academia

Using Pellet 3D printing as a means to drive

the next generation of engineers toward

a sustainable future.

Built for use

RESEARCH INITIATIVES SUPPORTED

Our commitment to advancing additive manufacturing is reflected in how our technology supports the furtherment of material science, sustainability efforts, and large-scale manufacturing processes. By fostering workflows in these areas, we are helping investigate & generate dependable results through our Additive Manufacturing systems.

Composite Materials Development & Characterization

Progressive Construction Strategies

Pellet 3D Printing for Energy & Sustainability

Large Format Additive Manufacturing Processes

Techno-Economic Analysis & Project Management

Advanced Propulsion Technology & Tooling

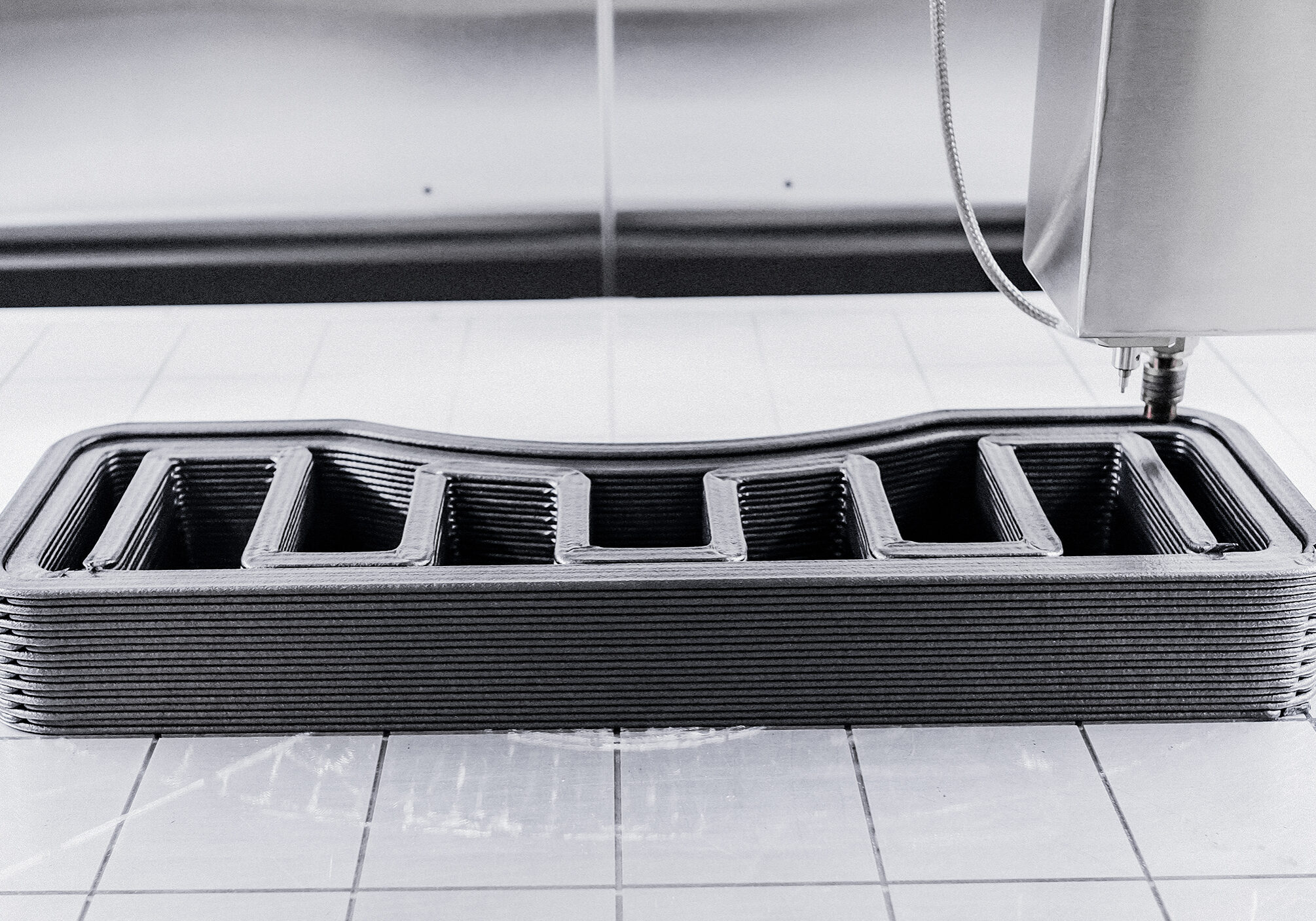

Sophisticated Printing

We are committed to driving innovation at rapid speeds and delivering advanced material processing capabilities. Through JuggerBot 3D’s advanced additive manufacturing technology we discover the capability of concentrated part production for analysis.

Use High-Performance Materials

Pellet 3D printing offers the advantage of opening the portfolio of performance thermoplastics into the thousands. As this continues to grow, additive systems need to be able to handle high-temperature materials as well as complex reinforcing agents. Our standalone and self-contained systems allow quick iterations of repeatable & reliable test samples.

Expert Support & Service

We pride ourselves on our service packages to make sure that everything from site assessment to remote-support is available to ensure project success.

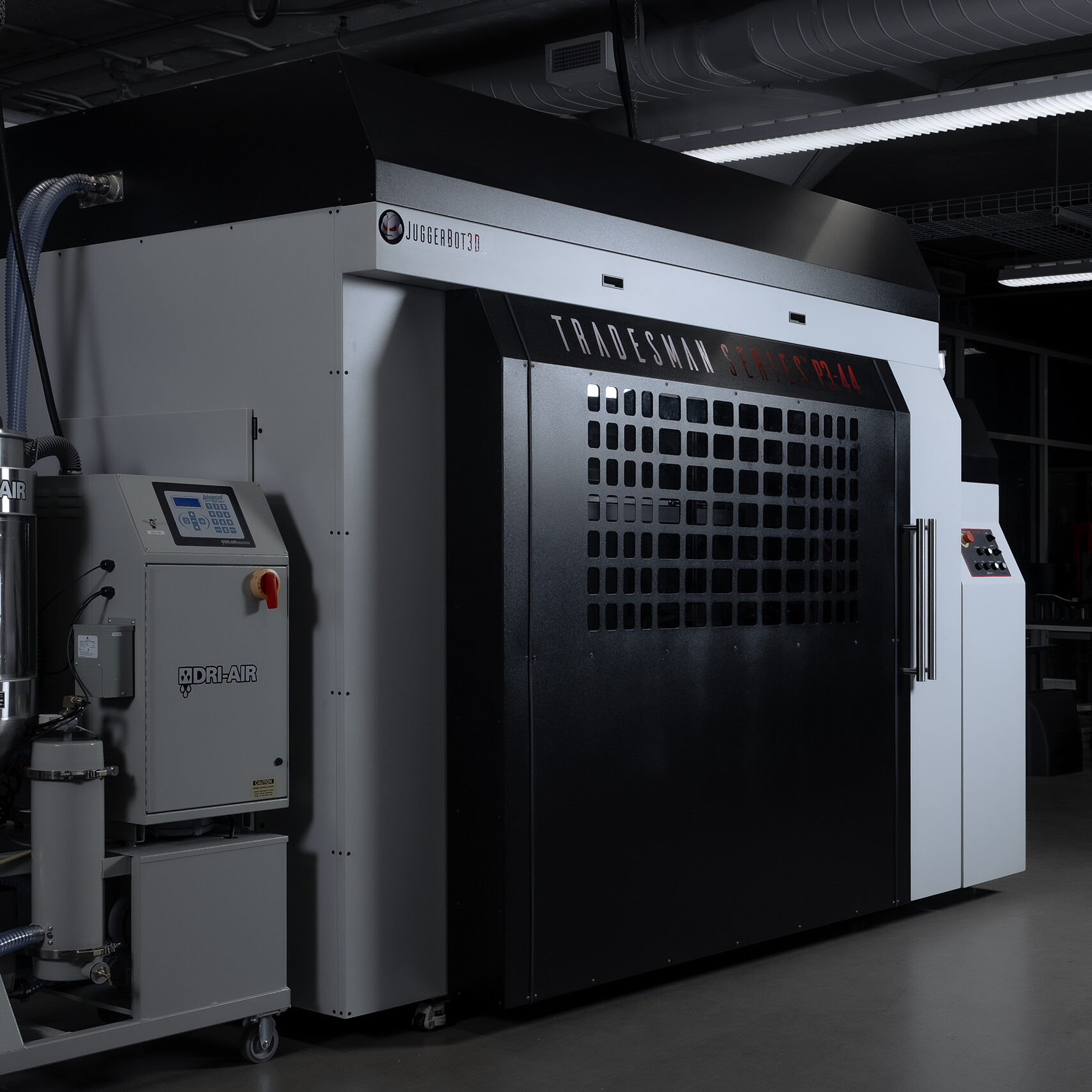

The Tradesman Series™ P3-44

Control and Develop

Built for engineers, our open system is completely material agnostic & able to process a wide range of performance thermoplastics. Use tools built into our system to understand your developments with heightened control. From an enclosed chamber, heated build plate, and sophisticated calibration technologies, develop parts with controlled process conditions through our Large Format Pellet 3D Printer.

Why JuggerBot 3d?

+ Process controls to work for you in any environment

+ Advanced Material Processing Capabilities

+ Test Validation for Commercial Readiness

+ Sophisticated Calibration Processes

Collaborators

Who we Support

Since 2016, we have aligned with America Makes in their mission of working together to accelerate the adoption of AM and the nation’s global manufacturing competitiveness. Through this, we have been able to accelerate relationships with advanced research centers such as the uMaine Advanced Structures & Composites Center (ASCC), Oak Ridge National Laboratory (ORNL), and Weber State University's MARS Center to aid in propelling the next generation of manufacturing forward.

Request a Briefing on our Additive Manufacturing Solutions

Our Large Format systems are designed to meet you where you are. Get in touch with a member from our team to educate us on your research initiatives & see where we can collaborate and fit into your projects.

You might also be interested in these topics

Use Case

Creating Agile Production of People Movers

Read our case study on how Fused Granulate Fabrication (FGF) 3D Printing solved supply chain issues and deployed over 400 pounds of printed material in just 8 Days.

JB3D

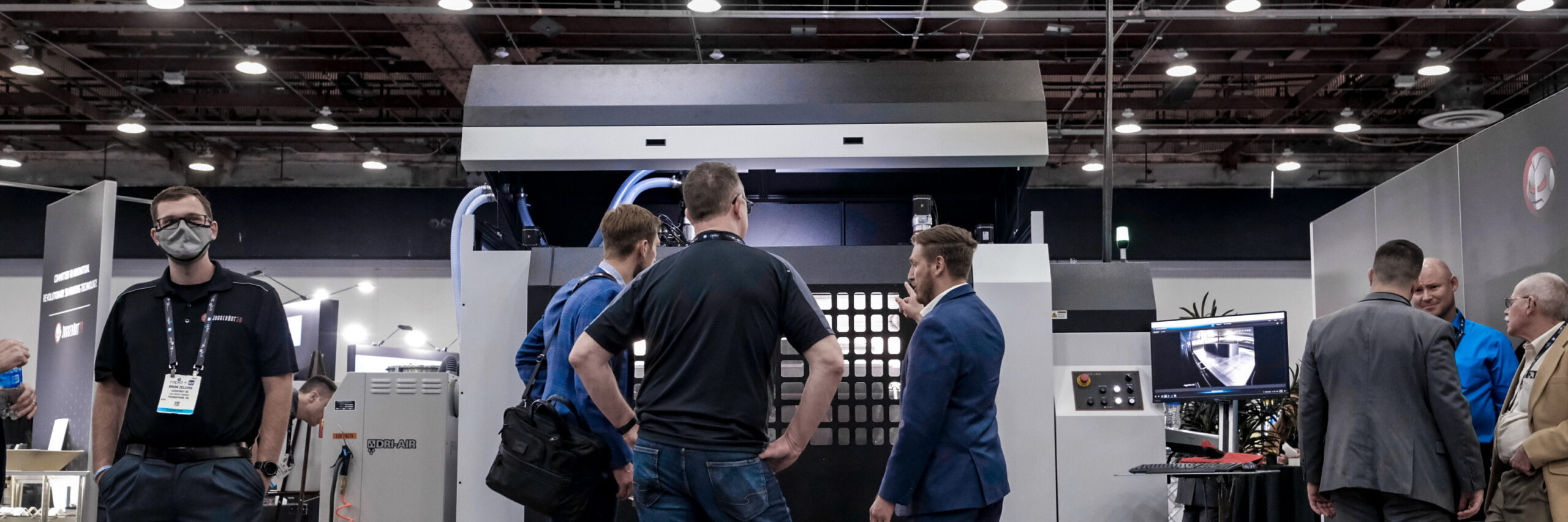

Events & Trade Shows

On the road again. Meet with JuggerBot 3D staff to go over the latest developments in large format additive manufacturing.

Technology

JuggerBot 3D Material Card

Enabling production workflows with open material 3D printing systems. Our smart technology leverages skills, material and process data to streamline production.