The Juggerbot 3d

Material Card

We are excited to unveil our first Material Card, enabling

production workflows with open material 3D printing systems.

Our Material Card is product that leverages material and process data to streamline production,

bridge skill-gaps, and improve reliability

ISSUES IN APPLICATION

Several considerations need to be accounted for in the production process. Is the material dry enough? Does the print have a consistent flow rate? Is the part going to be strong enough?

This is not a clean process in a production environment.

The JuggerBot 3D Material Card is a streamlined approach to overcoming these obstacles in Production 3D Printing.

See for yourself

material card demo

Join JuggerBot 3D President/Co-Founder Zachary Divencenzo to go over the fundamentals & operations of the Material Card in order to create a streamlined production workflow with Pellet-Fed 3D Printing.

AREAS COVERED

-Bead Characterization System (BCS)

-Bead Area Mode (BAM)

-Material Database

-Using the Material Card in the production environment

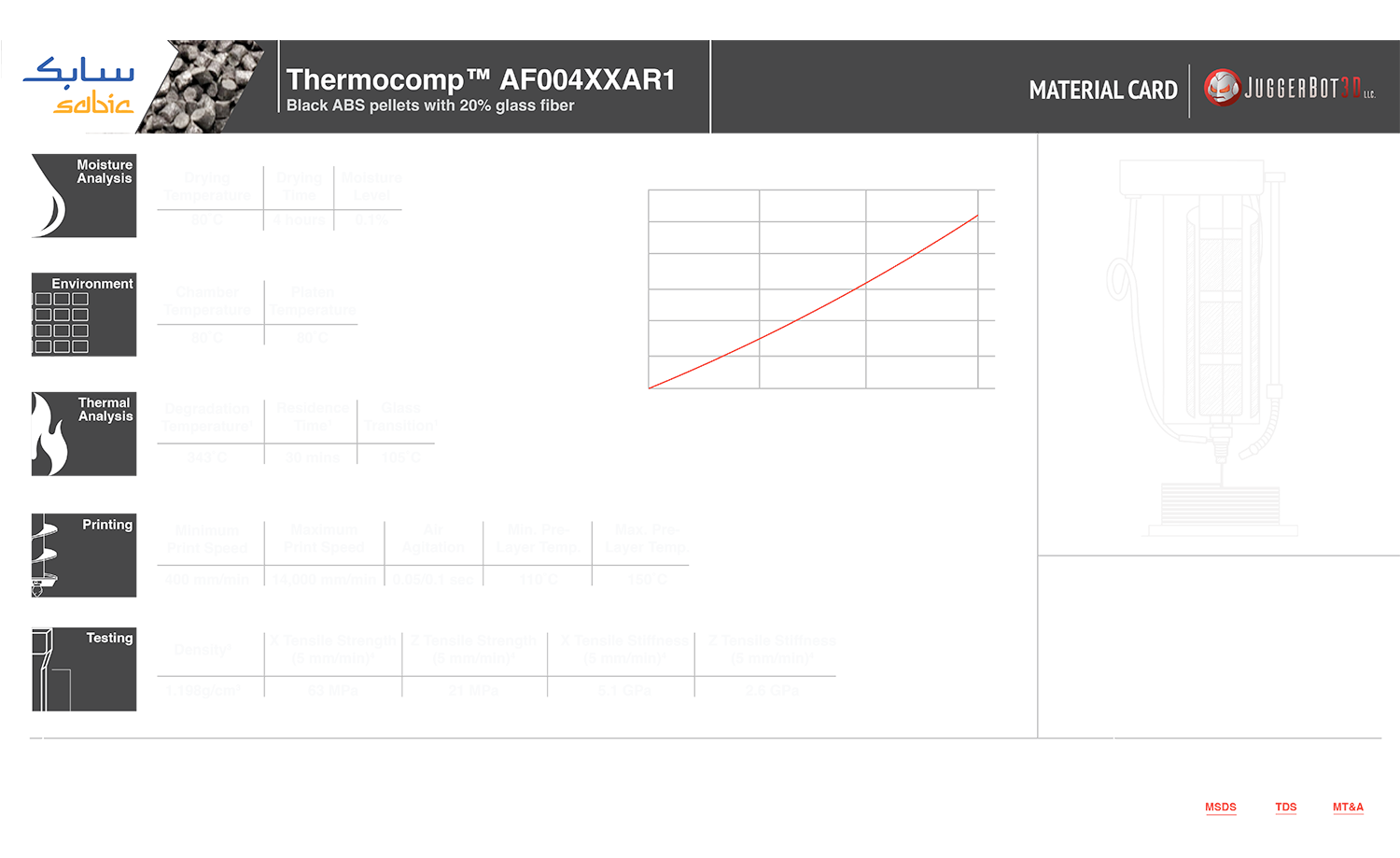

THE MATERIAL CARD

Enabling production workflows with open material 3D printing systems. Our Smart Technology leverages material and process data to streamline production, bridge skill gaps, and improve reliability.

MATERial testing

& Assessment

The first step to set up a production workflow.

Building the foundation for processing materials with pellet-fed additive manufacturing.

The Material Testing & Assessment procedure utilizes sophisticated instruments and technology to develop fundamental process parameters for new materials.

Bead

characterization

system (BCS)

Collects critical data points that characterize the extrusion path

Sophisticated calibration process that stabilizes the bead geometry, ultimately reducing overall operator interference. Bead Characterization is a stable & reliable procedure to acquire model parameters.

Bead AREA MODE (BAM)

a method for generating tool paths for 3D printing based on the Bead Characterization System

The entire tool path (and process parameters) is built based on the desired geometry of the bead.

Once the BCS operation is complete, an operator can simply designate the desired bead width and layer height, and the remainder of the parameters are set based on the BCS data. This results in a significantly faster process that’s a better fit for the dynamic nature of pellet-fed additive manufacturing.

MATERIAL DATABASE

Serves as the primary directory for Material Card data and operation

A chronology of materials tested by JuggerBot 3D to accurately organize and display thermoplastics & composites on a project basis.

Interested in adding your material to our datbase?

Drop us a line and we’ll hand-craft your material card.

want to learn more?

Material card faq

The JuggerBot 3D Material Card is an extended suite of tools and technologies to streamline the production workflow. View this page to understand common questions of pellet 3d printing materials while using one of our key products.