Ready to find out more?

Drop us a line today for a free quote!

What is ASA?

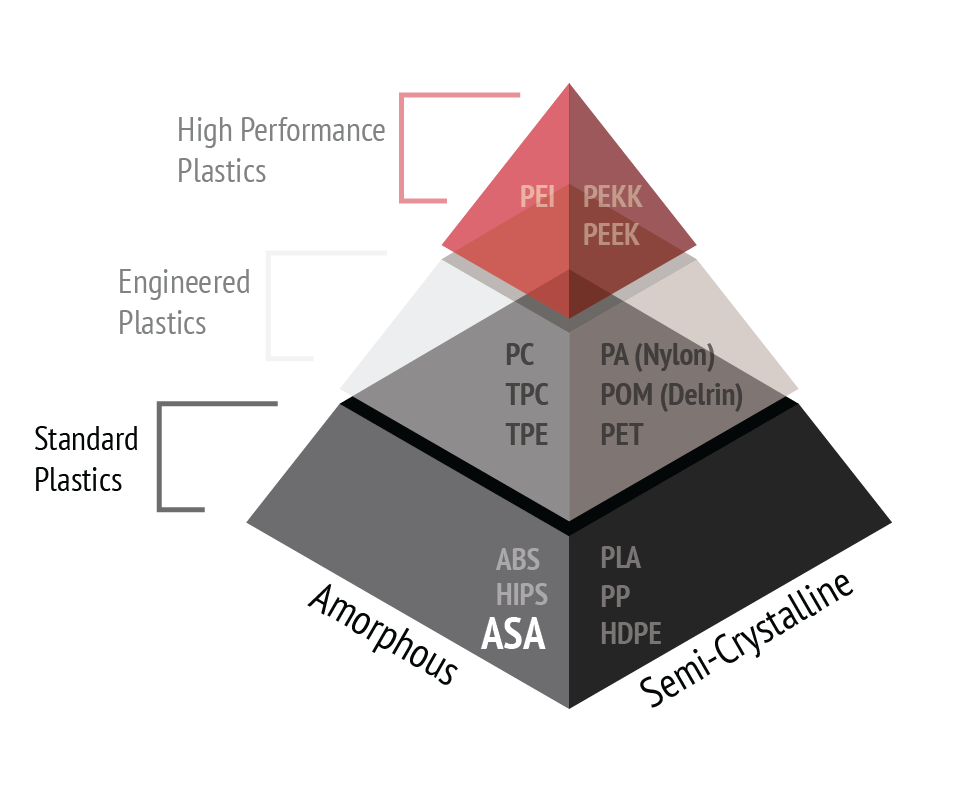

Acrylonitrile Styrene Acrylate (ASA) is a synthetic, amorphous thermoplastic that works best in material extrusion printing. It is a high impact material that can be used to produce functional parts for automotive applications, electronics, tooling, and more. It is known for having high weather and UV resistance, making it a great candidate for outdoor applications.

What CAN YOU USE ASA FOR?

ASA FOR 3D PRINTED TOOLING

ASA is an affordable 3D printing material that demonstrates good mechanical performance and resistance to the elements. It is a material that can be used to produce:

- Workholding jigs and fixtures

- End-of-arm tooling (EOAT)

- Inspection gauges

- Assembly fixtures

ASA FOR 3D PRINTED PROTOTYPES

ASA is relatively easy to print and affordable, making it great for iterative design. Due to its strength properties and UV resistance, ASA can be used to produce functional prototypes, including:

- Molded components for Auto, Marine, and RV applications

- Electrical housings

- Outdoor appliances

- Hand and power tools

- Sporting goods

- Exterior signage

ASA FOR PRODUCTION 3D PRINTING

ASA is primarily used in 3D printing for producing high impact, durable products that require heat, water, and UV resistance. Below is a list of some of the notable products that can be printed with ASA:

- Automotive Exterior Parts

- Marine and RV Applications

- Outdoor Applications

- Electrical/Electronic Applications

- Construction Applications

- Lawn and Garden Equipment

- Electronic Displays Sheet

Consult your engineering team to understand the limitations for 3D printed parts compared to those made traditionally.

ASA Performance Features

- High impact resistance

- Strong UV and chemical resistance

- Water resistant

- Anti-static properties

- Tough and durable

- Low-gloss finish

ASA material properties

Typical mateiral properties for molded ASA test specimen include:

- Tensile Strength: 35.0 - 50.5 MPa

- Tensile Modulus: 1,786 - 2,468 MPa

- Elongation at Break: 25 to 40%

- Elongation at Yield: ≅ 5.01%

- Flexural Strength: 38.6 - 78.6 MPa

- Flexural Modulus: 1,413 - 2,606 MPa

- Glass Transition Temp: ≅ 112 °C

- Heat Deflection Temp (1.8 MPa): ≅ 92 °C

- Hardness: ≅ Shore D 110

- Density: 1.06 - 1.09 g/cc

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

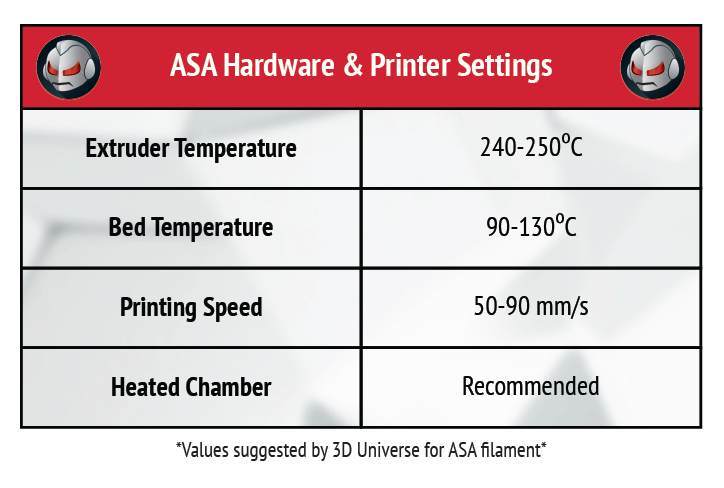

Printer Requirements and Settings

Due to its high glass transition temperature, a heated bed is required to successfully print with ASA. For the best results when printing with ASA, a fully enclosed print bed is recommended.

While the ranges may not vary greatly from one brand of material to another, operators should always check for the suggested printing parameters provided by the material manufacturer. Your machine manufacturer can also be a great resource for processing knowledge.

3D Universe suggests the extruder temperature be set between 240℃ and 250℃, the bed temperature to be set between 90℃ and 130℃, and for the printing speed to be 50-90 millimeters per second.

3D Printing with ASA - the procedure

Depending on part size and geometry, 3D printing ASA may come with some small challenges. Be sure to dial-in to the appropriate print parameters for best results, specifically regarding the print speed, extruder temperature, and bed temperature. ASA should be dried before, and kept dry during printing. It is recommended that ASA be processed on an enclosed 3D printer to promote adequate layer-to-layer adhesion and combat warpage. We suggest investing in a good build surface, which may include Kapton (AKA polyamide) tape, PET sheets, or using an adhesive as necessary.