Ready to find out more?

Drop us a line today for a free quote!

What is PET?

This page covers the pure PET, sometimes referred to as ‘PETP’. We will cover other PET modifications, including PETG, on separate pages.

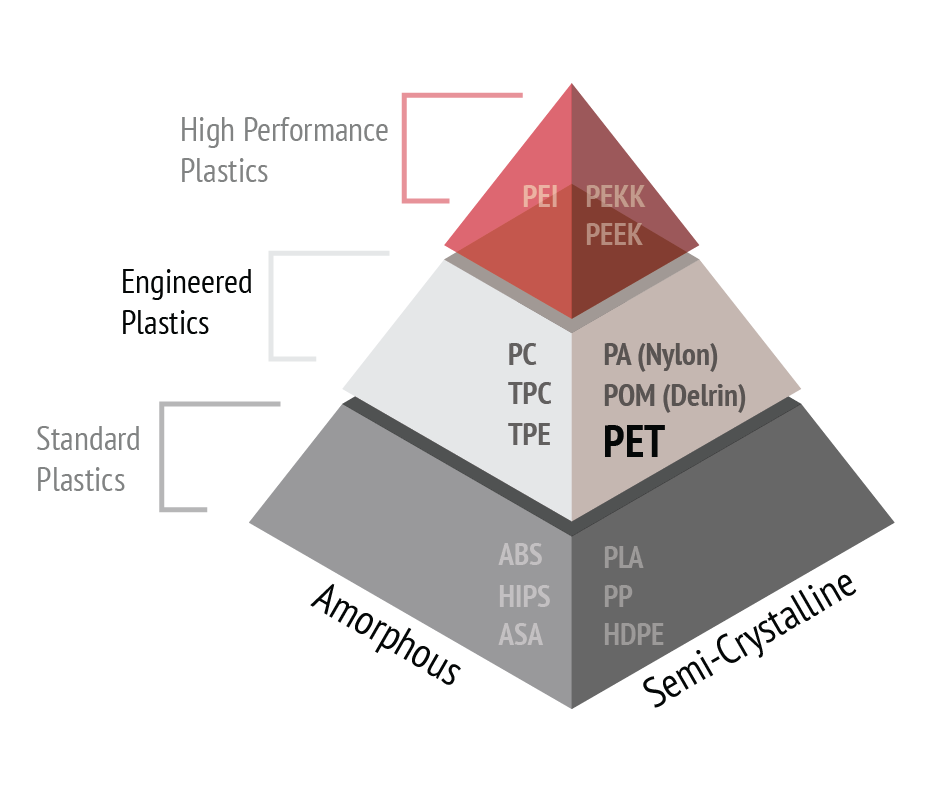

Polyethylene Terephthalate (PET) is a polyester-based 3D printing material that combines excellent mechanical, electrical and thermal properties with very good chemical resistance and dimensional stability. PET also has low moisture absorption features and good flow properties, making it a great material to use for waterproof containers such as food and beverage storage. It is a great material to use for making lightweight products such as potted planters, insulated bottles, or tupperware.

It is a 100% recyclable material, but recycled material may have a softer surface that could make it prone to wear and tear.

PET ApplIcations

PET is a thermoplastic available in many forms for traditional manufacturing. PET is available in pellets for injection molding and extrusion, as well as in sheet for thermoforming. PET filament can therefore be used to mimic the performance of products we come in contact with on a regular basis, and can also be used in some tooling applications.

PET for 3D Printed Tooling

PET can be used to produce tooling as a stronger, stiffer alternative to ABS, including:

- Thermoforming molds

- Jigs and fixtures

- Assembly aids

PET for Prototypes and Production 3D Printing

PET can be a suitable material for electronic applications requiring good heat resistance, dimensional stability, strength, and/or chemical resistance, including:

- Lighting frames

- Lamp housings

- Check valves

- “White good” connectors

Consult your engineering team to understand the limitations for 3D printed parts compared to those made traditionally.

PET Material Properties

Typical properties for molded PET test specimen include:

- Tensile Strength: 42.5 - 63.6 MPa

- Tensile Modulus ≅ 3,500 MPa

- Elongation at Break ≅ 70%

- Elongation at Yield ≅ 4.5%

- Flexural Strength ≅ 82.5 MPa

- Flexural Modulus ≅ 2,450 MPa

- Glass Transition Temperature ≅ 70°C

- Heat Deflection Temperature (1.8 MPa): 71.6 - 80.0°C

- Hardness ≅ Shore D 82

- Density ≅ 1.4 g/cc

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

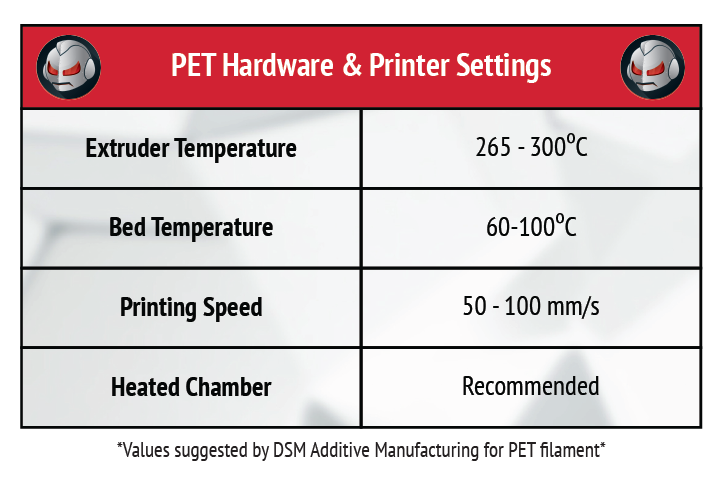

3D PRINTER Requirements AND SETTINGS

PET filaments may be processed with common fused filament fabrication (FFF) extrusion techniques.

Different brands and strands of PET may require changes to the processing parameters and/or configuration of a 3D printer. Operators should always check for the suggested printing parameters provided by the material manufacturer. Your machine manufacturer can also be a great resource for processing knowledge.

DSM Additive Manufacturing suggests a print speed between 50-100 millimeters per second, and states that the preferred extruder temperature be set to 270°C, although the material can be extruded between 265°C and 300°C. They recommend setting the bed temperature between 60°C and 100°C, and an enclosed printer is preferred to best results.

3D Printing with PET - the procedure

It is critical that operators take the proper material handling precautions to prevent moisture pick up and contamination. DSM Additive Manufacturing suggests bringing cold material up to ambient temperature in its closed packaging to prevent moisture condensing on filament. Material should be dried at 80°C for at least four hours.

Operators are encouraged to make sure the 3D printer is “cleaned” before and after production. For instance, DSM Additive Manufacturing suggests extruding at least 50 millimeters of material through the nozzle before starting a print, and purging the nozzle with PLA or PETG after printing. They also advise operators to remove PET filament from the machine before shutdown.

An enclosed build chamber is recommended for printing PET, and a heated build chamber is preferred. The build surface should be free of direct and grease, which can be cleaned with ethanol or acetone before applying any adhesion promoters, such as Magigoo, 3D-Lac, or glue.

After a part is finished printing, operators may want to leave the printed part in ambient conditions for at least four hours post production.

Contributor's Bio:

Greg Costantino is the New Business Development and Application Specialist at DSM Additive Manufacturing, a business unit of Royal DSM, NV. He is responsible for developing and executing the strategy for business development in the N. America region. Some of his key responsibilities are identification and analysis of markets for growth, strategic planning, project management and coordination of new product development.

Greg Costantino | New Business Development & Application Specialist | DSM Additive Manufacturing

DSM – Bright Science. Brighter Living.™

Royal DSM is a global science-based company active in health, nutrition and materials. By connecting its unique competences in Life Sciences and Materials Sciences DSM is driving economic prosperity, environmental progress and social advances to create sustainable value for all stakeholders. DSM delivers innovative solutions that nourish, protect and improve performance in global markets such as food and dietary supplements, personal care, feed, pharmaceuticals, medical devices, automotive, paints, electrical and electronics, life protection, alternative energy and bio-based materials. DSM’s 23,500 employees deliver annual net sales of around € 9 billion. The company is listed on NYSE Euronext. More information can be found at www.dsm.com.