from defense manufacturing conference (DMC) 2023

Emerging Direct Ink Writing Capabilities for

Functional Soft Matter Applications

Taken from the joint presentation "Emerging Direct Ink Write Capabilities for Functional Soft Matter Applications" given at the Defense Manufacturing Conference on December 14, 2023.

Presentation Speakers:

Dr. Shane Esola; U.S Army DEVCOM / Armaments Center

Mr. Zac DiVencenzo; JuggerBot 3D

Presentation Abstract

Additive manufacturing (AM) is a transformative technology that is integral to Industry 4.0, an industrial evolution concept leveraging advanced/smart/digital manufacturing, and a high-priority national growth area. Extrusion-based methods such as fused filament fabrication (FFF) have achieved vast proliferation, market penetration, and scientific advancement in the last decade. While direct ink write (DIW) has not garnered the same attention as FFF, it offers significant flexibility in functionally tailored soft matter that creates unique application opportunities in diverse industry sectors like food, pharmaceuticals, ceramics, synthetic biomaterials, construction, energy, and defense. DIW provides a viable manufacturing path for dynamically graded, multi-material parts laden with functional solid materials suspended in a soft matrix. Parts can be architected at multiple scales leading to a metamaterial framework: from microscopic ink formulation manipulation to macroscopic control during manufacturing. Wide ranging defense applications of interest include biomimicry and soft robotics, flexible electronics and wearable sensors, synthetic biology, printed batteries/energy storage, composite tooling production, and printed seals/gaskets. The presentation will discuss advances in soft materials manufacturing via DIW, demonstrate use cases for functional soft materials in engineering applications, and introduce successfully transitioned soft DIW parts and processes. The objective is to advocate for increased industrial adoption of DIW to meet modern defense challenges and provide another tool in the advanced manufacturing kit of the Defense Industrial Base.

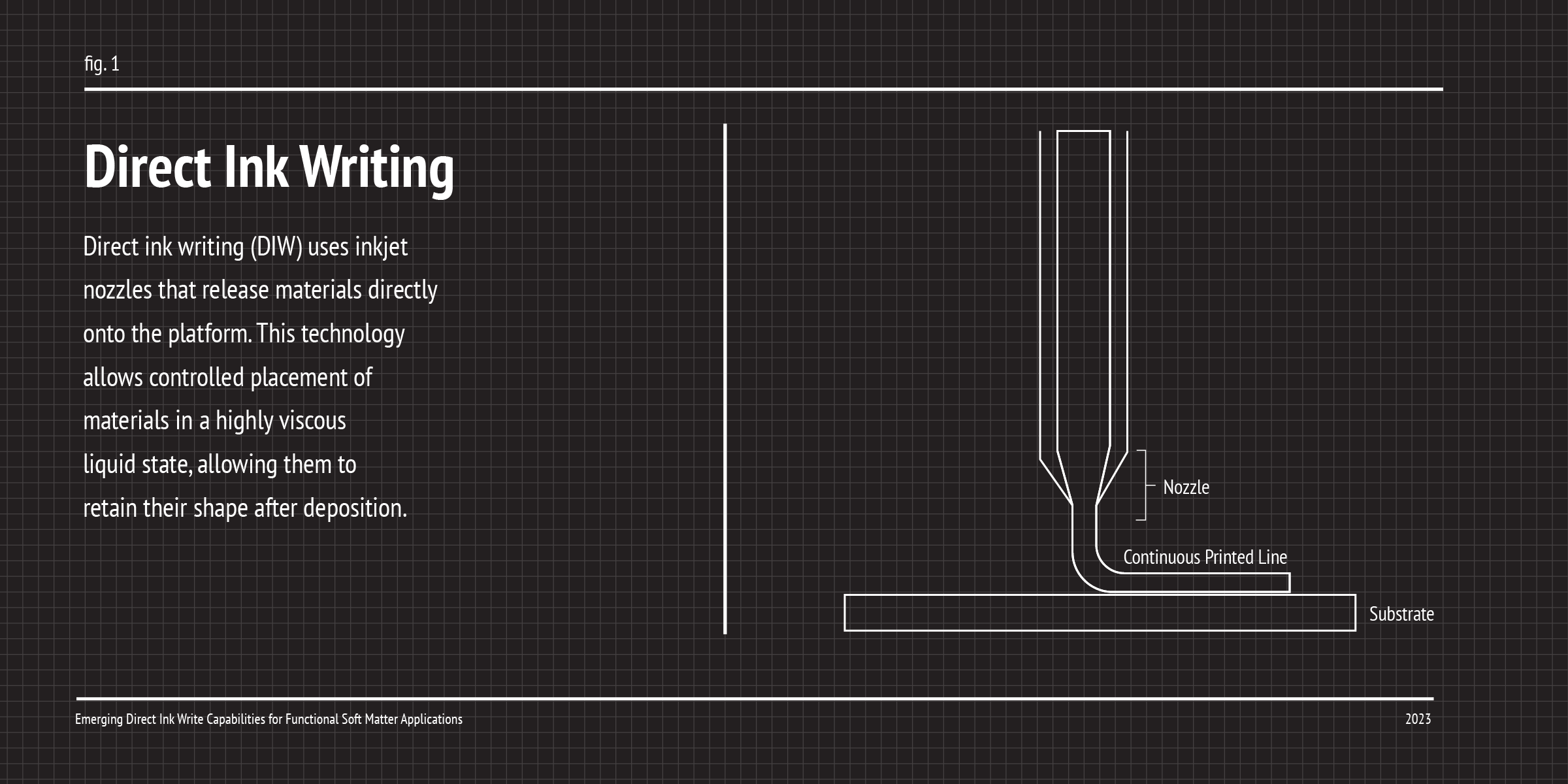

Conceptually Simple

Imagine squeezing cake icing out of a tube to draw a pattern or write your name, but on a much smaller and more controlled scale. Researchers and engineers can use a variety of materials to build intricate and customized 3D structures layer by layer.

Advantages Over Alternative Methods

High degrees of versatility exist between deposited materials. Tailoring of thermoset or elastomeric materials can provide multiscale functionality at the point of need.

Wide Range of Materials & Applications

Due to varietal functional, multiple industry applications have been derived. All areas of existence can be considered, from food, pharmaceuticals, electronics, ceramics, synthetic biomaterials, construction, energy, and defense.

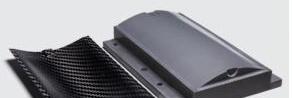

Gaskets & Seals

Seal leakages between two moving parts such as shafts, pumps, and engine parts. Prevent leakages between two flat surfaces of a component or a flange.

Energy Inks

Enables customized devices from batteries, catalysts, and fuel cells to heat exchangers and desalination devices, among others.

Tooling

Generate agile mold making processes in order to dramatically shorten workflow. Develop tools that demand less waste while decreasing the reliance on unique skills.

"Direct ink writing is an underappreciated and underutilized additive manufacturing mode"

-Shane Esola, Ph.D. ; US ARMY

Takeaways from Presentation

- There are advantages over traditional means, FFF, and other AM modes.

- It’s conceptually simple (who hasn’t put icing on a cake?)

- Enables advanced engineering materials.

- AGILITY! TAILORED MULTISCALE FUNCTION!

- Materials by design

- Rapidly gaining technical and manufacturing maturity

- Several business have started to offer applied industrial solutions relevant to DoD

- Should be considered as part of manufacturing strategy

- Mixed-mode/hybid mfg

- Enabling functions