Tradesman Series™ P3-44

Industrial Large Format FGF 3D Printer boasting enhanced printing speeds and material possibilities for manufacturers moving additive to the shop floor.

Build Bigger,

Faster.

The P3-44’s gantry, precision linear guides, and industrial-grade extrusion system are engineered for continuous operation of high-performance parts.

Technical Data

System Details

Printer Specifications

Build Volume 36 x 48 x 48 in (914 x 1219 x 1219 mm)

Machine Footprint 73 x 125 x 101 in (1854 x 3175 x 2565 mm)

Machine Weight 4,400 lbs (1996 kg)

Max Extruder Temperature 752°F (400°C)

Max Chamber Temperature 203°F (95°C)

Max Platen Temperature 248°F (120°C)

Max Throughput Up to 15 lbs/hr (6.8 kg/hr)

Dryer Capacity 100-150 lbs (45 - 68 kgs)

Suggested Layer Height: 0.030 - 0.089 in (0.75 - 2.25 mm)

Material Compatibility: ABS, PC, PEI/ULTEM, PEEK, PP, PA, PEKK, PET, PETG, PPSU, and more.

Technical Data

Pellet 3D Printing Materials

JuggerBot’s 3D Large Format 3D Printers are able to process a wide array of performance thermoplastics. From PETG to PEI, Tradesman Series™ printers are uniquely capable of printing these materials through

Process Controls → Sophisticated Calibration → Data Driven Processing

Composite Material Capability

Fiber Reinforcement: Glass, Carbon, Aramid

Sustainable: Wood Flour, Hemp, Cellulose, Coal

Nanoparticles: Carbon Nanotubes

Exotic Composites: Metal Powder Reinforcement

Technical Data

System Details

Pellet 3D

Printing Materials

JuggerBot’s 3D Large Format 3D Printers are able to process a wide array of performance thermoplastics. From PETG to PEI, Tradesman Series™ printers are uniquely capable of printing these materials through

Process Controls → Sophisticated Calibration → Data Driven Processing

Composite Material

Capability

Printer Specifications

Technical Data

System Details

Printer Specifications

Technical Data

Pellet 3D

Printing Materials

JuggerBot’s 3D Large Format 3D Printers are able to process a wide array of performance thermoplastics. From PETG to PEI, Tradesman Series™ printers are uniquely capable of printing these materials through

Process Controls → Sophisticated Calibration → Data Driven Processing

Composite Material

Capability

Fiber Reinforcement: Glass, Carbon, Aramid

Sustainable: Wood Flour, Hemp, Cellulose, Coal

Nanoparticles: Carbon Nanotubes

Exotic Composites: Metal Powder Reinforcement

Fast, Accurate, and Scalable

LFAM Parts That Perform

✔ Industrial-Ready Outputs

Engineered for production with pellet-fed extrusion, high-flow nozzles, and heated build platens up to 120°C for demanding thermoplastics.

✔ Strong, Fast Builds

High-output printheads and rigid gantry construction reduce cycle times and enable large, strong parts with desirable accuracy.

✔ Material Flexibility

Open material platform supports reinforced, high-temp, and sustainable pellets — including CF-nylon, PC, TPU, and PVC* — for unmatched application range.

*PVC compatibility available with ASTRA option.

Fast, Accurate, and Scalable

LFAM Parts That Perform

✔ Industrial-Ready Outputs

Engineered for production with pellet-fed extrusion, high-flow nozzles, and heated build platens up to 120°C for demanding thermoplastics.

✔ Strong, Fast Builds

High-output printheads and rigid gantry construction reduce cycle times and enable large, strong parts with desirable accuracy.

✔ Material Flexibility

Open material platform supports reinforced, high-temp, and sustainable pellets — including CF-nylon, PC, TPU, and PVC* — for unmatched application range.

*PVC compatibility available with ASTRA option.

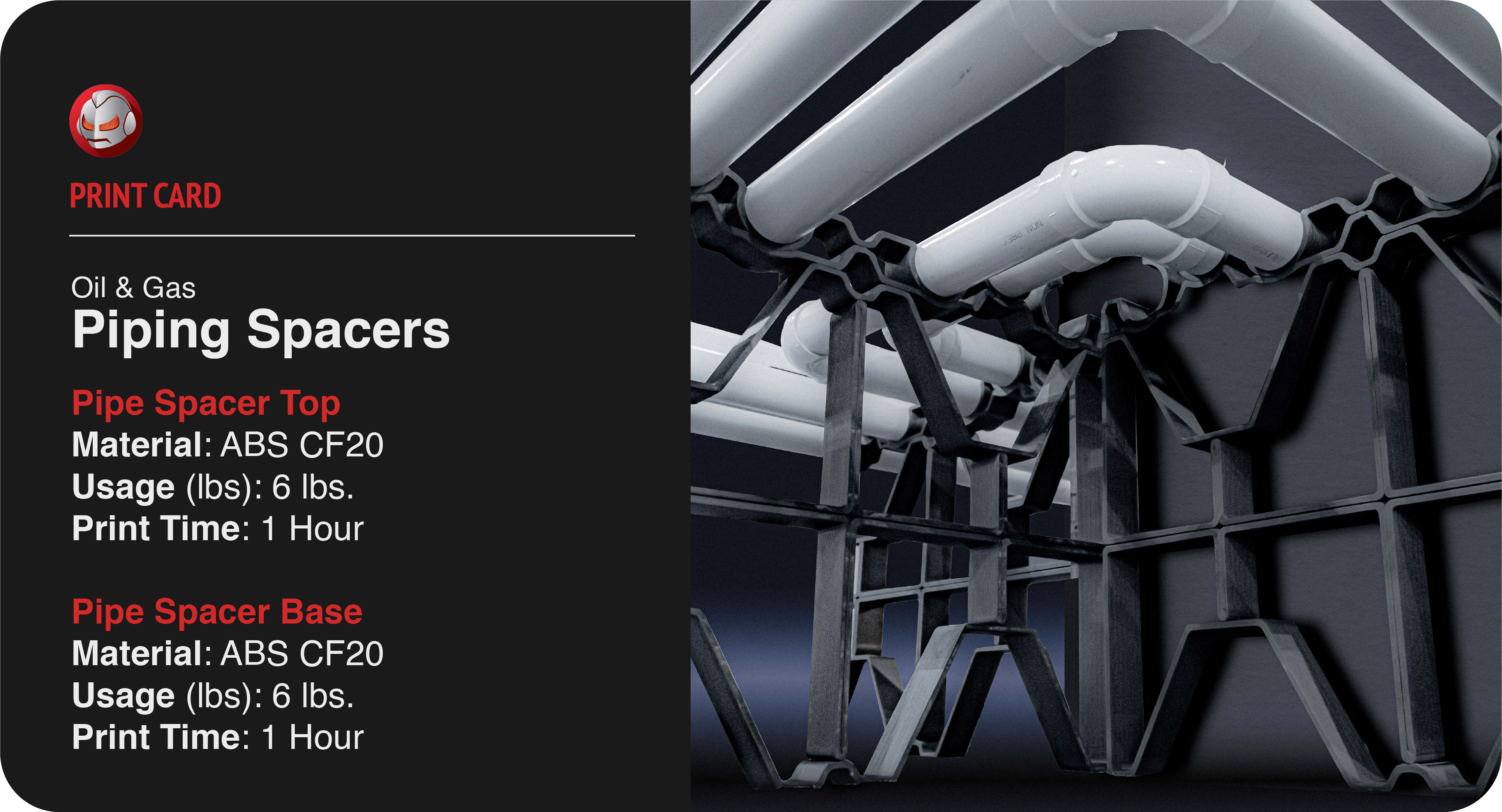

Additive Innovation

JuggerBot 3D

Material Card

The JuggerBot 3D Material Card is an extended suite of tools and technologies to streamline the production workflow. Leveraging fundamental process parameter development with sophisticated bead characterization.

Control & Flexibility

Smart Software &

3D Printing Calibration

All P3-44s are built with an integrated workstation that includes the complete suite of tools necessary for operation, including professional slicing software and machine control programs that include a library of processing information.

Calibration

Precise placement of the extruder nozzle is critical to quality control in 3D printing but can be time consuming. JuggerBot 3D’s calibration software uses touch probe sensing technology to simplify the bed-leveling process and repeatedly set nozzle position with ease.

In Use

Large Format

Applications

Our patented state-of-the-art printers focus on performance, reliability and value - reducing lead times, cutting costs, and opening the door to new possibilities.

Applications

- Low-Volume Manufacturing

- 3D Printed Composite Tooling

- Production 3D Printing

- Shielding Manufacturing

- Energetics Processing

- And More...

Get in Touch

See if the P3-44 Fits Your Workflow