Ready to find out more?

Drop us a line today for a free quote!

What is Nylon?

Nylons are a family of synthetic polymers composed of polyamides and are the material of choice for many demanding additive manufacturing applications. They tend to be semi-crystalline and are very tough. Nylons are available in different grades (PA6, PA11, PA12, etc.) and are often used when good mechanical strength, good stability under heat, and/or chemical resistance are required.

What 3d printing applications use nylon?

Nylons (polyamides) are used in an incredibly diverse range of applications. Nylon is used in the textile industry for fabrics, carpets, rope, and even strings for musical instruments. It is also a widely-used material for injection molding, especially in the production of vehicles and mechanical equipment. Nylon is also commonly machined to produce industrial components, and is commonly used as a light-weight alternative to low-strength metals.

Nylon has become a staple in industrial 3D printing, finding use for functional prototypes, 3D printed tooling, and production applications.

Nylon for 3D Printed Tooling

Nylon can be 3D printed to produce a number of industrial components, including, but not limited too:

- Robotic end-of-arm-tooling

- Gears, bushings, and bearings

- Wear pads

- Pulley wheels / sheaves

- High-strength jigs, fixtures, and production aids

Nylon for Prototypes and Production 3D Printing

While some variations may be better fit for certain applications, than others, Nylon is a great material for parts that require good mechanical properties, chemical resistance, and resistance to heat. Specific performance features, price, and processability will all play a role in identifying the best Nylon for the application.

DSM Additive Manufacturing’s Novamid® product line offers both a Nylon 6 (PA6) and a Nylon 6/66 (PA6/66) for filament 3D printing. Prototype or production 3D printing applications for Novamid® include, but are not limited too:

- Consumer products like power tools, furniture

- Industrial products found on conveyor systems, electrical components, and piping.

- Machinery products, including agricultural machinery, business machines, construction equipment, and military equipment.

- Automotive components, including door handles, under the hood components (air intake components, covers and housings, radiator end tanks, brackets, connectors), and safety systems.

- Aerospace applications, especially in cases where Nylon can be used as a light-weight alternative to metal.

Nylon Performance Features

Different grades of Nylon have varying properties. In general, Nylons exhibit:

- Excellent Retention of Stiffness

- Good Long-Term Heat Stability

- Superb Wear/Abrasion and Friction Behavior

- Excellent Toughness Level at various temperatures

- Excellent Fatigue Resistance at elevated temperatures

- Good Chemical, Oil and Hydrolysis Resistance

Main benefits of Nylon 6 (PA6):

- Excellent long-term heat ageing resistance

- Very good toughness at low temperatures

- Easy colorability

- High welding strength

Main benefits of Nylon 6/66 (PA6/66):

- Good flow behavior

- Good surface finish

- Easier processing/printing

Nylon Material Properties

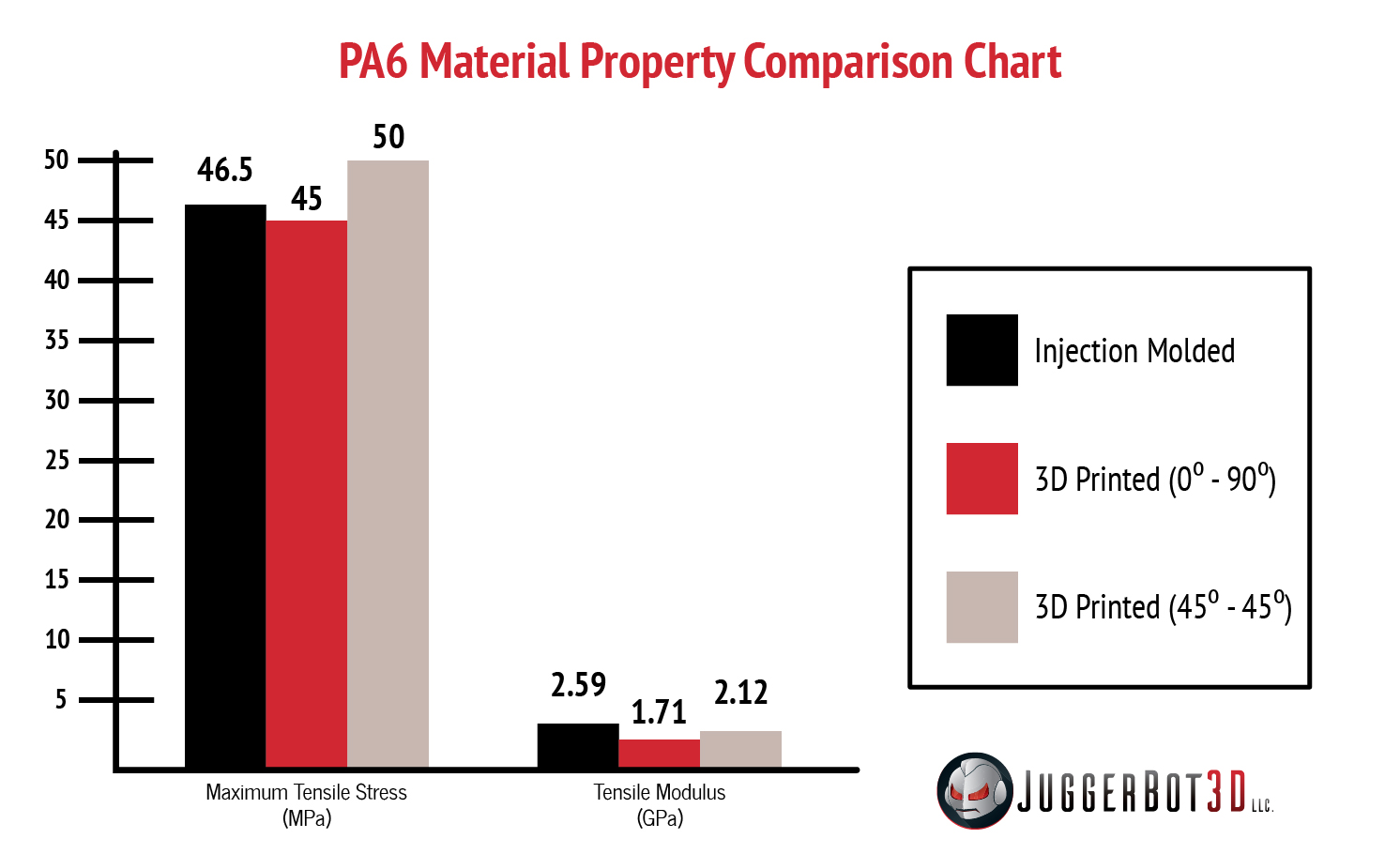

The following data below is provided by DSM Additive Manufacturing for molded test samples of dry Novamid® ID 1070 (Nylon 6):

- Tensile Modulus: 2,590 MPa

- Yield Stress: 77 MPa

- Yield Strain: 4.2 %

- Stress at Break: 46.5 MPa

- Strain at Break: > 50%

- Flexural Modulus: 2,680 MPa

- Flexural Strength: 108 MPa

- Melting Temperature: 220°C

- Heat Deflection Temperature (0.45 MPa): 104°C

- Water Absorption: 12%

- Density: 1.120 g/c

Due to the anisotropic properties of 3D printed parts, designers and operators may want to work with vendors in order to obtain data for 3D printed specimens. For reference, mechanical properties for Novamid® ID 1070 has also been provided from printed tensile bars:

- Maximum Tensile Stress (0° - 90°): 45 MPa

- Maximum Tensile Stress (45° - 45°): 50 MPa

- Tensile Modulus (0° - 90°): 1,710 MPa

- Tensile Modulus (45° - 45°): 2,120 MPa

- Elongation at Break (0° - 90°): 7.2%

- Elongation at Break (45° - 45°): 15.0%

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

As seen with many other plastics, Nylon’s material properties can be engineered to meet the requirements of more demanding applications. For instance, Novamid® ID 1030 is also available with carbon fiber reinforcement. See how an unfilled material compares to a reinforced one on our Novamid® ID 1030 CF10 page.

FFF Printer Requirements and Settings for Nylon

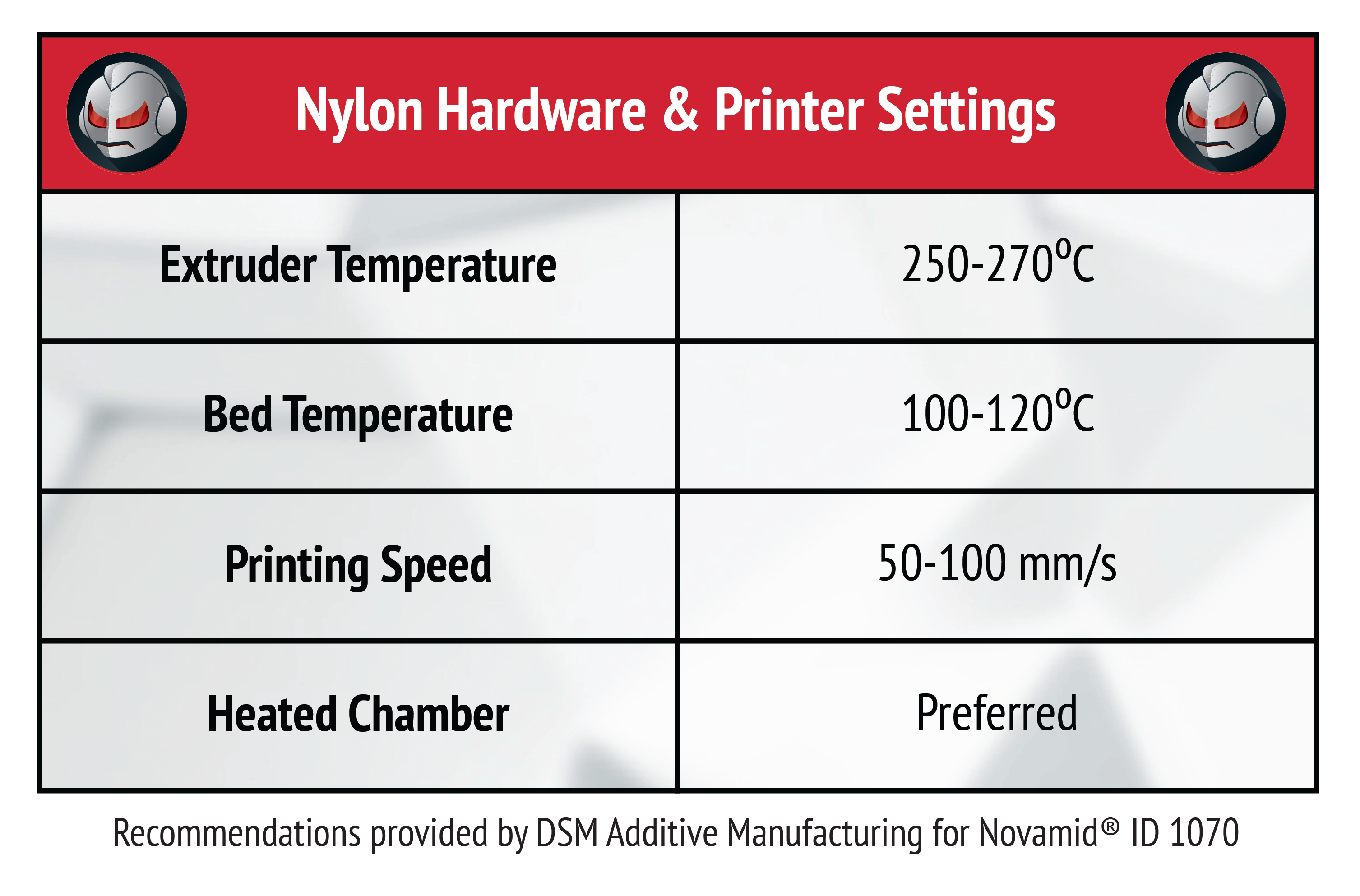

For best results when printing Nylon, using a 3D printer with a heated bed and environmentally-controlled build chamber is suggested.

JuggerBot 3D’s printers are stand-alone, incorporating a material dryer, an independently controlled loading bay, and environmentally-controlled build chambers. Learn more by visiting our product page!

For Novamid® ID 1070, DSM Additive Manufacturing prefers an extruder temperature of 260°C, a print speed between 50-100 mm/s, and an optimum print bed of 110°C. A heated build chamber is strongly preferred, helping to reduce the warpage and fusion of layers during printing.

3D Printing with Nylon - the procedure

Polyamides are hygroscopic by nature, meaning they readily attract water from their surroundings, through either absorption or adsorption. “Wet” material will cause problems during printing, and so Nylon must be dried before use according to the manufacturer’s specifications. For Novamid® ID 1070, DSM Additive Manufacturing suggests drying the filament in a desiccant dryer for four hours at 80°C. Alternatively, in a convection oven at 80°C, but longer drying time will be necessary.

Operators should make sure their 3D printer is clear of residual material before starting, and are therefore encouraged to extrude at least 50 millimeters of new filament through the nozzle prior to beginning a print. Either PLA or PETG can be used to purge materials Nylon.

For best adhesion with Nylon, like Novamid®, operators are advised to use an adhesive promoter and/or a build plate made of PEI or fiber-reinforced epoxy. Before applying an adhesive promoter, the build surface must be free of dirt and grease. Therefore, cleaning with ethanol or acetone is recommended.

For Novamid®, DSM Additive Manufacturing suggests the extruder temperature to be set as close to 260°C as possible, the bed temperature set as close to 110°C as possible, and for a heated, enclosed build chamber to be in place for best results.

Prior to removing the printed part from the bed, bed temperature should be lowered to ambient in order to avoid severe deformation of the part.

Contributor's Bio:

Greg Costantino is the New Business Development and Application Specialist at DSM Additive Manufacturing, a business unit of Royal DSM, NV. He is responsible for developing and executing the strategy for business development in the N. America region. Some of his key responsibilities are identification and analysis of markets for growth, strategic planning, project management and coordination of new product development.

Greg Costantino | New Business Development & Application Specialist | DSM Additive Manufacturing

DSM – Bright Science. Brighter Living.™

Royal DSM is a global science-based company active in health, nutrition and materials. By connecting its unique competences in Life Sciences and Materials Sciences DSM is driving economic prosperity, environmental progress and social advances to create sustainable value for all stakeholders. DSM delivers innovative solutions that nourish, protect and improve performance in global markets such as food and dietary supplements, personal care, feed, pharmaceuticals, medical devices, automotive, paints, electrical and electronics, life protection, alternative energy and bio-based materials. DSM’s 23,500 employees deliver annual net sales of around € 9 billion. The company is listed on NYSE Euronext.