Ready to find out more?

Drop us a line today for a free quote!

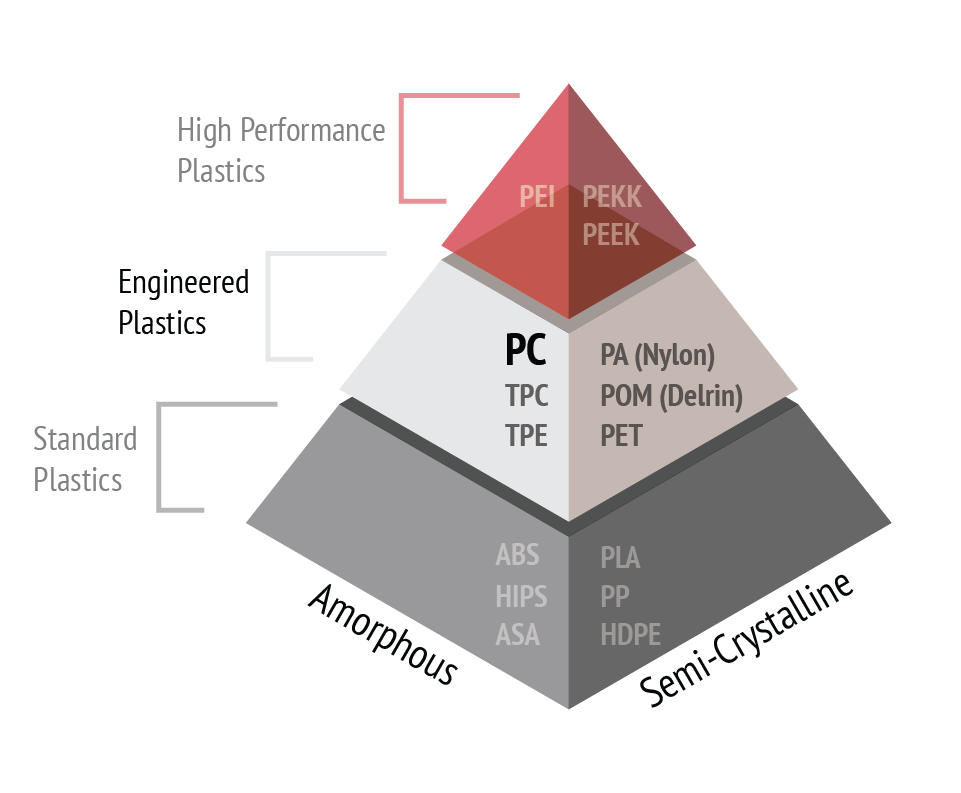

What is Polycarbonate (PC)?

Polycarbonate (PC) is a high-performance, synthetic filament used for fused filament fabrication 3D printing. It is a recyclable material that can be engineered to meet specific application or processing requirements, such as low warping. It’s toughness and rigidity make it an ideal material for higher demanding 3D-printing applications.

Polycarbonate (PC) FFF Applications

The main applications for Polycarbonates are lighting, electrical and electronic equipment, and optical applications.

Examples include heavy light fixtures, data storage items such as discs, and telecommunication equipment such as phones and monitors.

The scientific name of the polycarbonate that will be referenced on this page is Addigy® GPC 3D 1000, a product of the Covestro group.

Polycarbonate (PC) for 3D printing

Polycarbonates can be produced as clear/transparent, which makes the filament a good choice for lighting and optimal applications.

Polycarbonate can also offer good heat resistance and flame retardance, like Covestro's Addigy® GPC 3D 1000, having a Vicat softening point of up to 114°C. The material is flame retardant with a UL 94 rating of V2, making it ideal for electrical and electronic equipment.

Polycarbonate (PC) Performance Features

Polycarbonate is naturally transparent in color. Depending on the application, the material can be colored in a pre-processing step. Some materials, like 3DXTECH's 3DMAX PC, are engineered to promote easier processing and minimal warping.

Key features of most Polycarbonates include:

- Inherent transparency

- Low viscosity

- Heat resistant

- Flame retardance

- Tough and rigid

Polycarbonate (PC) Material Properties

The following information is provided by Covestro (formerly DSM Additive Manufacturing) for 3D printed test samples of Addigy® GPC 3D 1000.

- Density: 1210 kg/㎥

- Melt volume rate: 34㎤/10 min

- Vicant softening temperature: 112 ℃

- Young’s Modulus xy-direction: 2010 MPa

- Tensile strength xy-direction: 63 MPa

- Elongation at break xy-direction: 4%

- Impact strength yz-direction: 64kJ/㎡

- Burning behavior: V2

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

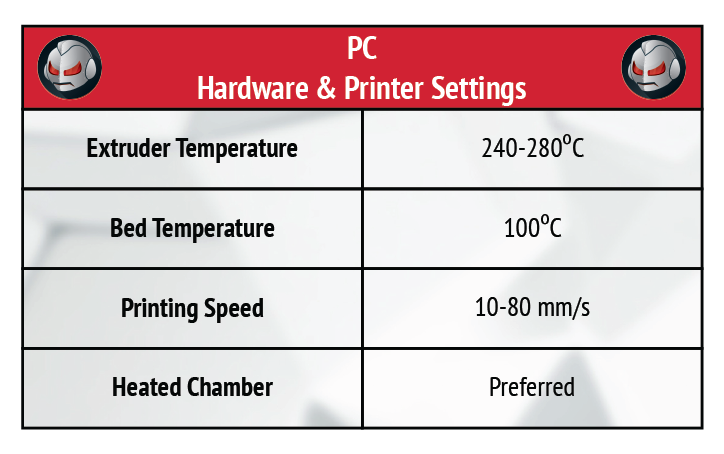

Printer Requirements and settings

Different brands and strands of PC may require changes to the processing parameters and/or configuration of a 3D printer. Operators should always check for the suggested printing parameters provided by the material manufacturer. Your machine manufacturer can also be a great resource for processing knowledge.

For optimal results, Covestro Additive Manufacturing suggests an extruder temperature between 240 and 280 °C. Pre-drying of the material is recommended at temperatures between 80 and 100 °C, with drying times between two and twelve hours to achieve a moisture content of ≤ 0.02%. Dried, hot material must not be allowed to cool in the open air. They should be stored in dry, resealable containers. The material must remain in a controlled environment at all times, even during printing to mitigate moisture absorption.

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

3D Printing with Polycarbonate (PC) - the procedure

Addigy® GPC 3D 1000 should be stored in its original packaging at all times. If bags or containers have been opened, they must then be sealed again to ensure proper further storage.

Prolonged exposure of bags or containers containing Addigy® filaments or pellets to light or light sources containing UV rays should be avoided. UV radiation will lead to degradation especially, but not limited to, color changes of the filaments or pellets and subsequently molded parts. Constant, normal room temperature with minimal fluctuations and low to normal humidity is essential. It is important to properly dry the filaments and pellets, as directed for the product, prior to processing.

Contributor's Bio:

Katinka Honervogt is the Global Marketing Manager of Covestro’s Additive Manufacturing Group. Located in Leverkusen, she oversees all marketing and communication activities in Europe, North America, and Asia-Pacific.

Katinka Honervogt | Global Marketing Manager | Covestro Additive Manufacturing Group