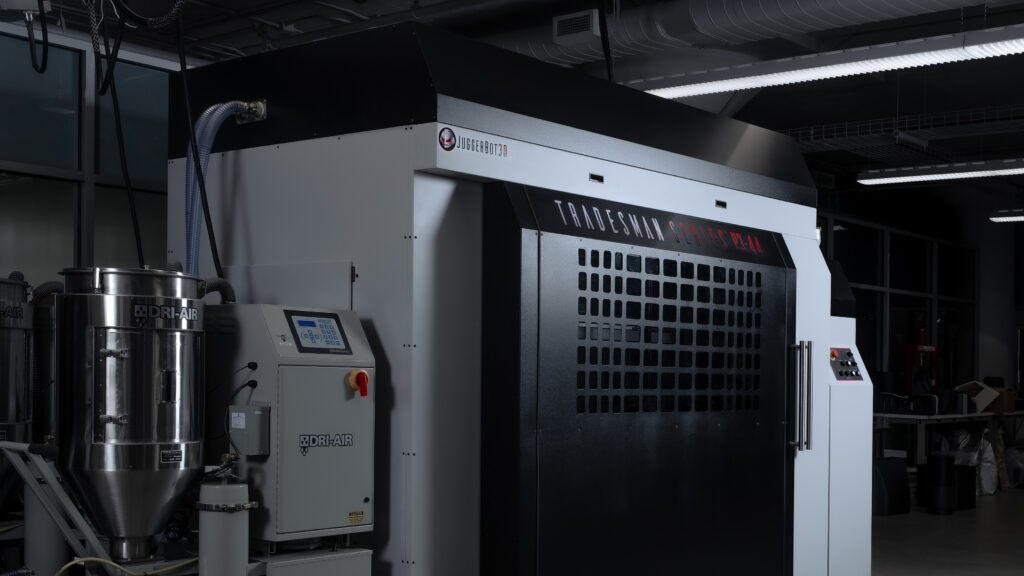

Tradesman Series™

F3-32

The Tradesman Series™ F3-32 is an industrial 3D printer boasting top-of-class build volume and open material architecture that accelerates tooling and low volume production with functional materials.

2023 Update

JuggerBot 3D is moving our product line to the pellet-fed additive manufacturing market with our Tradesman Series™ P3-44. We’re excited for you to explore our new additive manufacturing system, designed to meet the needs of engineers and operators alike. As we bid farewell to our Tradesman Series™ F3-32, we invite you to explore the future of pellet-3d 3D systems with our pellet-fed system.

Rapidly Produce Large Parts

The F3-32’s 36” x 36” x 24” build volume provides the space you need to make big parts in days, not months.

Low Material Price, High Functionality

Choose from a wide variety of third-party filaments, including flexible, high-strength, and some high temperature materials.

Professional Support and Service

JuggerBot 3D offers service and support programs to make sure your team gets the most of their Tradesman Series™.

Specifications

System Details

Printer Specifications

Extruder Specifications

Process Specifications

Software

Peak Extrusion Performance

Our patented filament extrusion system, AKA the Interdependent Drive System, makes it easy to process a range of diverse material options. By utilizing both push and pull forces on filament throughout the extrusion process, risks of slippage or clogging are drastically reduced – even with flexible or reinforced materials!