Ready to find out more?

Drop us a line today for a free quote!

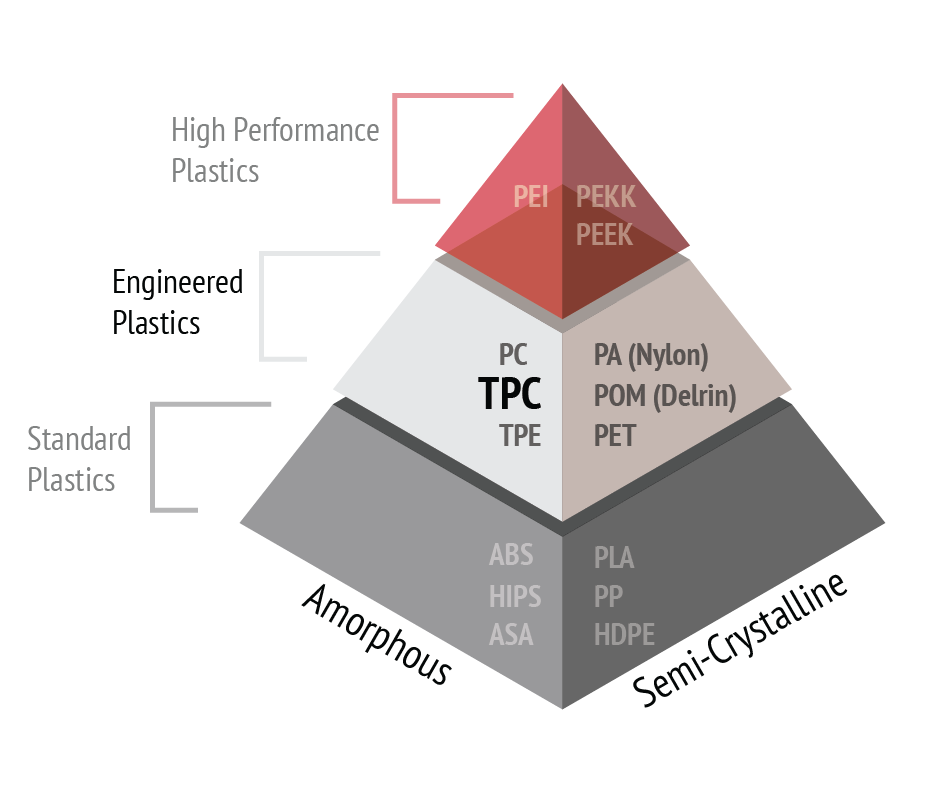

What is TPC?

Thermoplastic Co-Polyesters (TPCs) are a sub-set of thermoplastic elastomers (TPE) that combine properties of thermoplastics and rubber materials. In general, TPC can be used in a wide range of temperatures and allows for the retention of many of the original mechanical properties. It is a high flexibility filament with elastic behaviors that make it great for stretchable products and harsh environments.

3D Printed TPC APPLICATIONS

TPC can be used for products that stretch, compress, or bend because the material is highly elastic in nature. It performs well in harsh environments due to its rubber-like features, especially the outdoors.

TPC FOR 3D PRINTED TOOLING

TPC is a 3D printing material that demonstrates high elasticity and performs well under harsh environments, making it suitable for certain production environments. TPC is primarily used for 3D printed tooling projects such as:

- Bumpers, or other energy absorbing components

- Protective bellows and covers for moving parts

- Components where a soft-touch surface is needed (ie. Robot arms)

TPC FOR PRODUCTION 3D PRINTING

TPC can be used to create functional prototypes for parts that will ultimately be injection molded or extruded. It may also be an acceptable alternative for rubber parts manufactured via compression molding or transfer molding such as:

- Hose and tube

- AirDucts

- Softer Housing and covers

- Seals, gaskets

- Shock absorbers, bedsprings, pads

- Footwear

- Safety equipment

- Wearable devices

- Medical devices

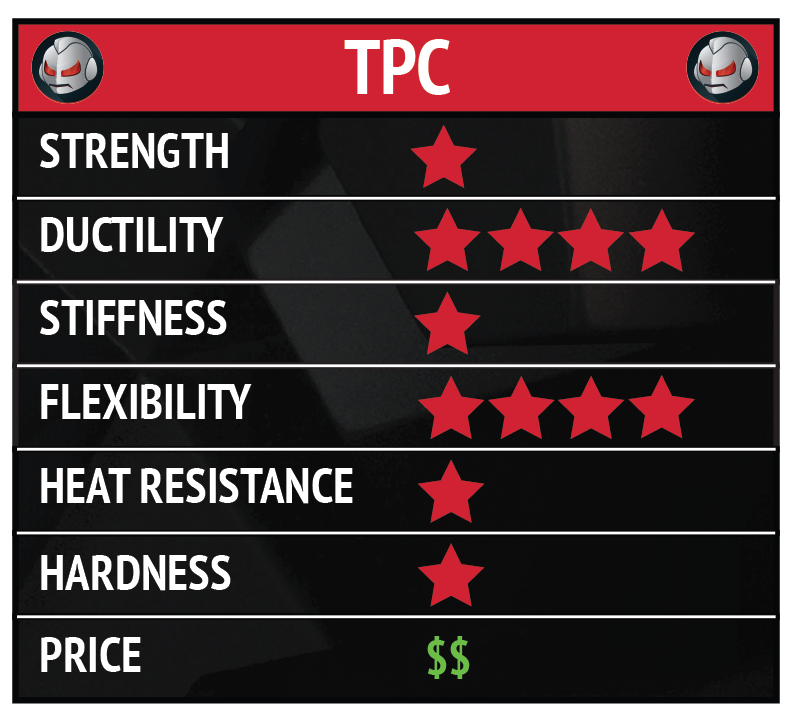

TPC Performance Features

- Mechanical performance at low temperatures

- Thermal performance

- Chemical resistance

- Rubber-like behavior

- Ductility

- Durability

TPC Product FEATURES

TPC performance capabilities as noted by several 3D printed specimens:

- Melt Temperature = 158C

- Glass Transition Temperature = -35C

- Vicat Softening Temperature = 90C

- Tensile Modulus = 29 MPa

- Maximum Tensile Stress = 8 MPa

- Elongation at break = 390 %

- Shore D Hardness = 34

*Note: These properties are for Arnitel® ID2045 from DSM.

Disclaimer: The above information is provided in good faith. JuggerBot 3D assumes no obligation or liability for the accuracy or completeness of the information supplied in this document. It is solely the customers responsibility to determine if the product and information in this document are appropriate for the customers end use. Responsibility for the use, storage, handling, and disposal of the products herein is that of the purchaser or end user.

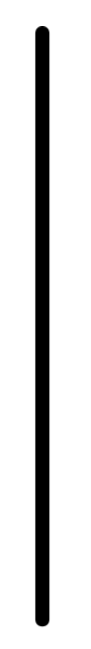

Filament 3D Printer Requirements and Settings for TPC

For 3D printing with TPC filament, the following procedure and process should be followed for optimal results.

The material should first be brought to ambient temperature in closed packaging to prevent possible moisture condensing on the filament.

In order to prevent moisture pick up and contamination, packaging should be kept closed and undamaged. For the same reason, partially enclosed bags should be properly sealed before re-storage.

Due to its flexible nature, direct drive extruders are recommended for the best quality print, as indirect drive extruders may be prone to clogging or inconsistent throughput.

Available TPC Filaments

DSM currently offers TPC filament under the tradename Arnitel® for flexible 3D printing, which is based on >50% renewable content. Common fused filament fabrication (FFF) equipment works well with Arnitel® filament. There are two different types of Arnitel® TPC:

Contributor's Bio:

Greg Costantino is the New Business Development and Application Specialist at DSM Additive Manufacturing, a business unit of Royal DSM, NV. He is responsible for developing and executing the strategy for business development in the N. America region. Some of his key responsibilities are identification and analysis of markets for growth, strategic planning, project management and coordination of new product development.

Greg Costantino | New Business Development & Application Specialist | DSM Additive Manufacturing

DSM – Bright Science. Brighter Living.™

Royal DSM is a global science-based company active in health, nutrition and materials. By connecting its unique competences in Life Sciences and Materials Sciences DSM is driving economic prosperity, environmental progress and social advances to create sustainable value for all stakeholders. DSM delivers innovative solutions that nourish, protect and improve performance in global markets such as food and dietary supplements, personal care, feed, pharmaceuticals, medical devices, automotive, paints, electrical and electronics, life protection, alternative energy and bio-based materials. DSM’s 23,500 employees deliver annual net sales of around € 9 billion. The company is listed on NYSE Euronext.