3D Printing 101 – Extruders

3D Printing 101: Extruders

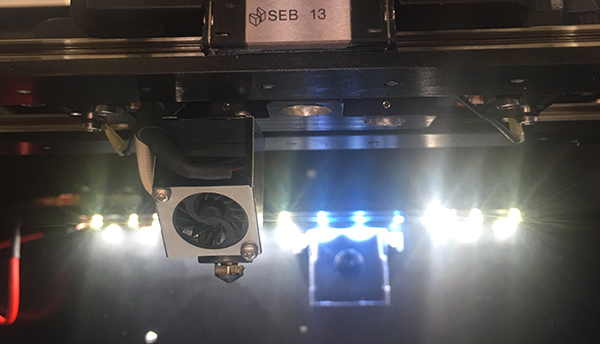

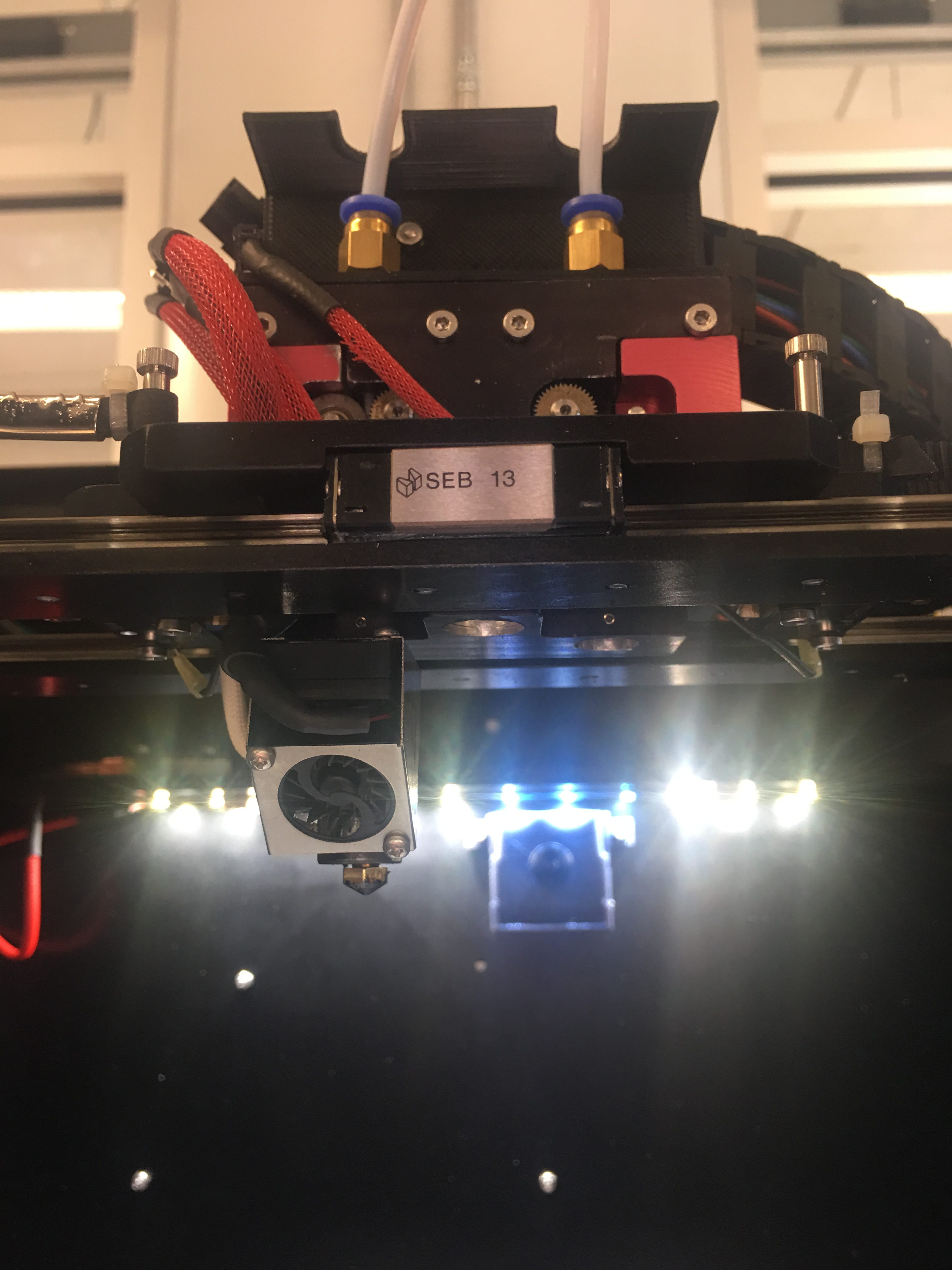

The extruder (head) on your 3D printer is the most essential component in the entire printing process, due to it being the place where most of the technology is located. Filament gets drawn into this head through a motor, heated, and then pushed out, similar to the process of a hot glue gun. The extruder is commonly mistaken as being the “hot end”, but this is actually the nozzle where the filament comes out. The extruder can basically be considered the “cold end”, because it is where the filament is prior to being pushed into the hot end.

What are the different types of extruders?

There are two different types of extruders: Direct and Bowden. The basic difference between the two is that the Direct extruder is connected directly to the hot end and the Bowden is not.

The Direct method uses a pulley/gear to pull the material into the hot end, and this allows for a quicker response time, which can allow for higher quality prints. This can also create problems due to the extra mass attached to the extruder, such as: backlash, overshoot, and frame wobble.

With the Bowden method, the hot end is attached to another part of the printer, and there is a tube that extends from the extruder to the hot end. This can allow your printer to be able to produce at a faster speed. It also can create more filament friction with more flexible materials and can create more lag in your print process.

Single vs. dual extruders

Dual extruders allow the capabilities of printing with multiple filaments, where two nozzles share the same head and move in one piece. The most useful function of dual extruders are the ability for the second nozzle to print support material, while the other nozzle prints your main structure. You can also print with multiple different colors of filament, and mass print small parts with a dual extruder.

Dual extrusion leads to more complexity of slicing and design of your prints. Single extrusion 3D printing still works perfectly fine for beginners, but if you are looking to dig deeper into 3D printing and want to get more interesting models, you may want to save up for a dual extrusion printer.

JuggerBot 3D currently has a patent-pending extrusion system to allow versatile printing abilities with confidence. For more information on extrusion systems and our patent, stay tuned for future posts here on our website!